The stator structure of the high-voltage and high-efficiency asynchronous start permanent magnet synchronous motor is similar to that of the ordinary Y series asynchronous motor. The company's R&D team uses modern high-performance motor design theory and design technology to optimize the core and winding; the rotor is placed in the high-performance rare earth “Magnetic King”, which optimizes the squirrel cage structure and can produce higher than ordinary asynchronous motors at rated voltage and rated frequency. Starting torque.

The rare earth "Magnetic King" is recognized as the world's most permanent magnet material with the highest magnetic energy content, saturated magnetization, and presents a "permanent magnetic field". After the motor is installed, no reactive current excitation current, permanent magnetic field of "Magnetic King", interaction with the three-phase current of the winding, and stable electromagnetic torque are generated to drive the load.

This structural feature of the high-voltage high-efficiency permanent magnet motor makes the power factor high. Under the condition of ensuring the same output power, the current is significantly reduced, the resistance loss of the winding is reduced, and there is substantially no rotor loss during operation, which exhibits remarkable high efficiency and energy saving characteristics. Due to the reduction of the total loss, the temperature rise is reduced by more than 30K compared with the conventional asynchronous motor, and the operating life is prolonged.

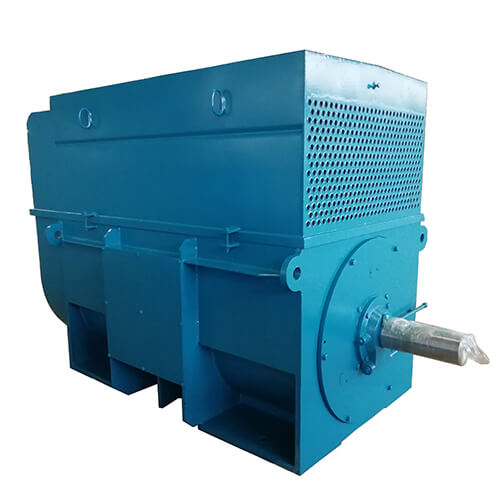

1.High-voltage high-efficiency permanent magnet synchronous motor, according to China JB/T 12681-2016 TYCKK series (IP44) high-efficiency high-voltage permanent magnet synchronous motor technical conditions, development and design.

2.High-voltage high-efficiency permanent magnet synchronous motor adopts rare earth high-function permanent magnet material, establishes working air gap magnetic field, does not need to draw reactive current excitation current from power supply, its power factor reaches above 0.96, and efficiency is generally increased by 2%-8% compared with Y series motor. In particular, the efficiency increases rapidly with the increase of load, maintains high efficiency in the range of 25%-120% wide load, and the product enters the national high-efficiency and energy-saving motor recommended catalog.

3.The high-voltage permanent magnet synchronous motor adopts the asynchronous starting method, and the product adopts the "no difference replacement" design technology with the Y series asynchronous high voltage motor. In addition, the product corresponds to the voltage level of the Y series high-voltage asynchronous motor, the installation size corresponds to the “no difference” replacement; at the rated voltage and rated frequency, it has self-starting capability, synchronous operation and no slip.

4.Widely used in electric power, metallurgy, chemical, building materials, water treatment, coal, mining, textile, rubber, glass, petroleum, transportation, medicine, paper, food and other industries.

5.Green production,helping enterprises reduce emissions, save energy, reduce consumption.

6.The basic series of motors are three-phase, 6KV, 10KV, 50HZ, air-to-air cooling, protection class IP54, class F insulation, IMB3 installation form, S1 working system. It can meet the requirements of users for other protection levels, cooling methods, installation forms, etc.

Center height range: H355 ~ 800mm

Power range: 185kW ~ 2500kW

Number of poles: 2/4/6/8/10/12

Rated voltage: 3000V/3300V/6000V/66000V/10000V/11000V

Rated frequency: 50HZ/60HZ

Protection level: IP54 or IP55

Insulation class: F

Working system: S1 (continuous)

Cooling method: IC611/IC616

Installation form: IMB3

Motor connection: Y (three outlet terminals in the junction box, the junction box from the extension of the spindle is located on the right side of the base)

Altitude: no more than 1000m

Requirements for use: altitude below 1000 meters, ambient temperature -15 °C ~ +40 °C.

This type of motor is suitable for use in environments where the ambient air temperature does not exceed 40 ° C and there is no serious dust, the minimum ambient air temperature is -15 ° C, and there is no corrosive and explosive gas in the air (which can also be made into a damp heat or high-altitude motor).

In addition to excellent energy-saving and high power factor characteristics, the high-voltage high-efficiency permanent magnet synchronous motor has the following advantages in motor operation and under load conditions:

1.The operating current is significantly reduced.

2.The temperature rise is reduced by more than 30K, and the operating life is prolonged.

3.Reduce the distribution network current and reduce the cable temperature rise.

4.Reduce the reactive power compensation capacity of enterprise distribution network.

5.The starting torque multiple is higher than the same power asynchronous motor, lifting heavy load starting performance.

1. The outer packaging of the products are all standard export-oriented wooden plywood packaging.

2. The product packaging is protected by moisture, water plastic soft packaging

3. For products with special transportation requirements (such as temperature, fragile, variability, and easy to get wet), the packaging protection measures will be strengthened, and the target mark will be printed on the package.

4. There are obvious signs and symbols on the packing box that must be paid attention to during transportation and storage (such as position, moisture, rain, shockproof, lifting position, etc.).

Factory Glimpse

Our company's motor manufacturing factory adheres to the concept of green, efficient and energy-saving production service, pays attention to the harmonious development of internal and external environment, builds environmentally friendly motor manufacturing enterprises, strictly implements motor standard process, and selects high-quality energy-saving materials to ensure the quality of motor products.

Customer Visit

The company insists on providing high-quality motor products and services to users, and has won high praise from many domestic and foreign customers. The company will receive many foreign merchants to visit our factory every year, and establish a good cooperative relationship through on-site inspection of our factory. Our company always welcomes customers to visit our factory.

Why Choose Us

1. Professional motor manufacturing service provider;

2. Sound product quality management and certification system;

3. Have a professional sales and technical service team;

4. The motor has perfect process and strong mechanical processing capability;

5. High standard product technical service system;

6. Good faith and mutual benefit, good credit guarantee.

how does a synchronous motor work

Large Permanent Magnet Synchronous Motor

The stator structure of the high-voltage and high-efficiency asynchronous start large permanent magnet synchronous motor is similar to that of the ordinary Y series high-voltage asynchronous motor.

Large Permanent Magnet Synchronous Motor

The stator structure of the high-voltage and high-efficiency asynchronous start large permanent magnet synchronous motor is similar to that of the ordinary Y series high-voltage asynchronous motor.

IE4 Low Voltage Ultra High Efficiency Permanent Magnet Synchronous Frequency Conversion Motor

The High Efficiency Permanent Magnet Motor is three-phase, 380V, fully enclosed fan air cooling, protection class IP54, class F insulation, installation form IMB3, working system S1.

IE4 Low Voltage Ultra High Efficiency Permanent Magnet Synchronous Frequency Conversion Motor

The High Efficiency Permanent Magnet Motor is three-phase, 380V, fully enclosed fan air cooling, protection class IP54, class F insulation, installation form IMB3, working system S1.

Copyright © ZCL Electric Motor Technology Co., Ltd. All Rights Reserved | Sitemap | Powered by