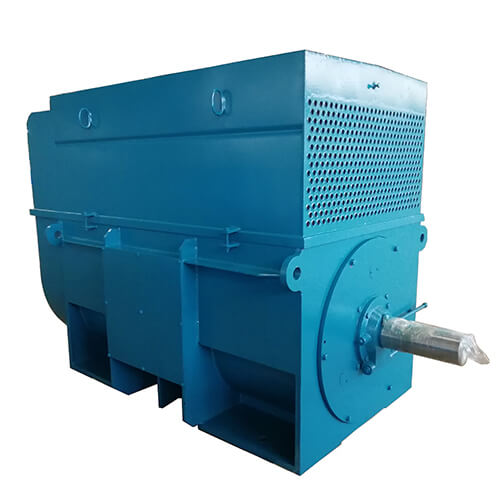

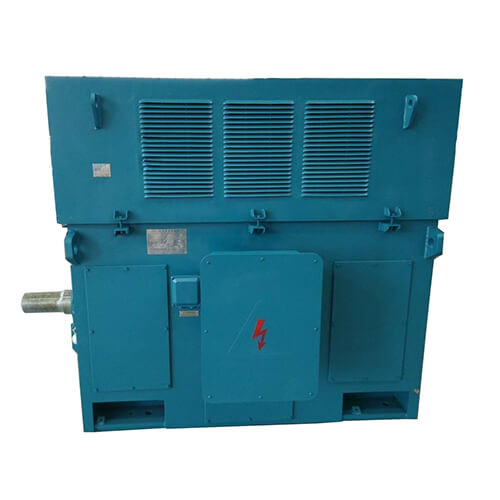

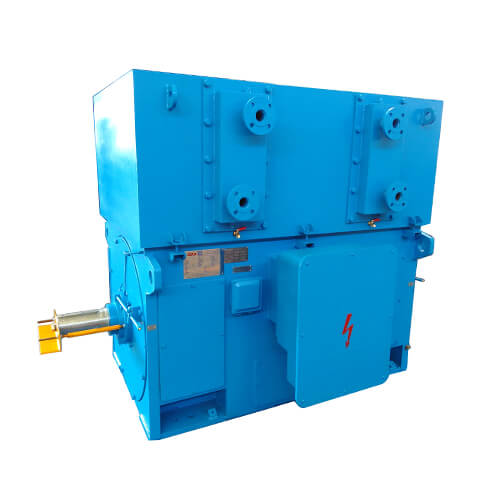

High Voltage Ribbed Cold Motor is a high-performance cast iron casing motor. The motor is a fully enclosed air-cooled motor. The newly designed cast iron casing has fins that conform to the air flow direction and have excellent heat dissipation during motor operation. This series of motors has an external external fan and the fan is made of steel.

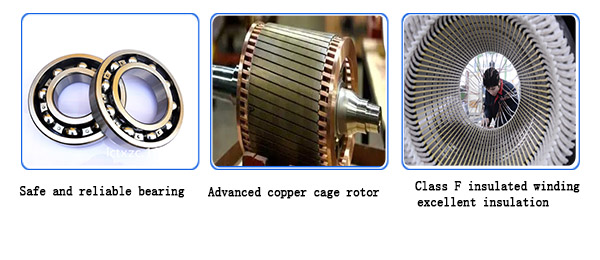

The High Voltage Ribbed Cold Motor rotor is a squirrel-cage structure with a state-of-the-art copper cage rotor that ensures greater load on the smooth running of the motor. Moreover, the rotor copper strip is processed by the in-tank fastening process, and thus has high reliability.

The High Voltage Ribbed Cold Motor stator features an external press fit. The stator winding adopts Class F insulation material and anti-corona material. The winding end is fixed by special lashing process, which is firm and reliable. The whole stator is treated with vacuum pressure immersion paint F-grade solventless paint (VPI). Thus, the motor has excellent and reliable insulation properties and moisture and impact resistance.

High Voltage Ribbed Cold Motor is a compact enclosed cage rotor three-phase asynchronous machine. The power class, electrical performance and installation dimensions and tolerances of the HXR series motors are in compliance with the International Electrotechnical Commission standard IEC/NEMA/CSA standards. The motor protection class is IP55 or IP56, and the cooling method is IC411 or IC416.

HXR series motors have the advantages of small size, compact structure, high efficiency, energy saving, low noise, low vibration, light weight, reliable performance, convenient installation and maintenance. This series of motors can be used to drive a variety of different machines. Such as ventilators, compressors, pumps, crushers, cutting machine tools and other equipment, and can be used for coal mines, machinery industry, power plants and various industrial and mining enterprises for the prime mover.

The structure and installation form of High Voltage Ribbed Cold Motor is IMB3 and IMB35. The quota is a continuous rating based on the continuous working system (s1) with a frequency of 50 Hz or 60 Hz and a rated voltage of 3 kV/6 Kv/10 Kv. Other voltage levels or special requirements can also be made.

Motor center high range: H355-H560

Rated power range: 150Kw-2250Kw

Rated voltage: 3000V/6000V/6600V/10000V/11000V

Number of motor poles: 2/4/6/8

Protection level: IP54/IP55

Cooling method: IC411

Rated frequency: 50Hz/60Hz

Insulation class: Class F

Installation method: IMB3/ IMB35/IMV1

High Voltage Ribbed Cold Motor has high efficiency, energy saving, compact structure, low noise, low vibration, high insulation grade, reliable quality, and meets many international standards. The motor is universal and has a wide range of applications.

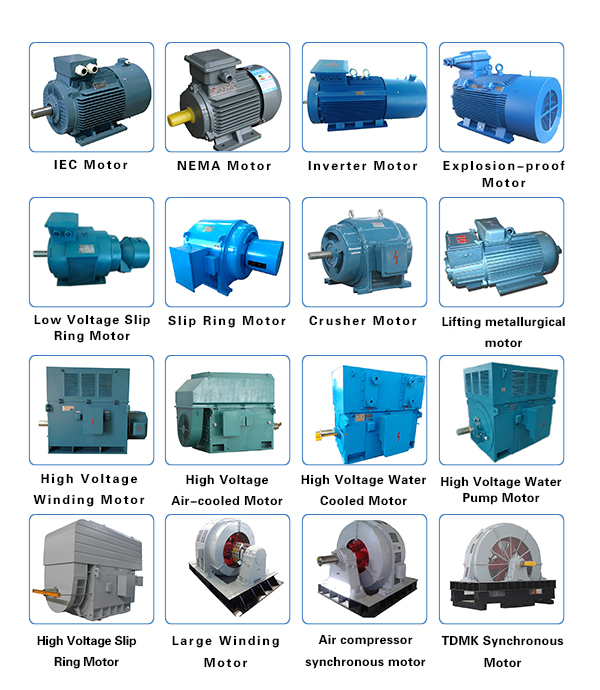

There are many types of motor products manufactured and sold by our company. The main products are high- and low-voltage three-phase asynchronous motors. The motor structure types include squirrel-cage type and winding type. Among them, high-voltage synchronous motors mainly support air compressors and mine ball mill equipment. use. We adhere to the service tenet of "focus on products, service with heart" and provide high-quality motor products to customers.

1. The outer packaging of the products are all standard export-oriented wooden plywood packaging.

2, the product packaging is protected by moisture, water plastic soft packaging

3. For products with special transportation requirements (such as temperature, fragile, variability, and easy to get wet), the packaging protection measures will be strengthened, and the target mark will be printed on the package.

4. There are obvious signs and symbols on the packing box that must be paid attention to during transportation and storage (such as position, moisture, rain, shockproof, lifting position, etc.).

Our company's motor manufacturing factory adheres to the concept of green, efficient and energy-saving production service, pays attention to the harmonious development of internal and external environment, builds environmentally friendly motor manufacturing enterprises, strictly implements motor standard process, and selects high-quality energy-saving materials to ensure the quality of motor products.

Why choose us (our service advantage)

1. Professional motor manufacturing service provider;

2. Sound product quality management and certification system;

3. Have a professional sales and technical service team;

4. The motor has perfect process and strong mechanical processing capability;

5. High standard product technical service system;

6, good faith and mutual benefit, good credit guarantee.

YTM/YHP/YMPS high-voltage asynchronous motor for coal mill

YTM, YHP, YMPS The motor torque-speed characteristic curve is relatively flat, the starting torque, the maximum torque and the minimum torque are all higher than 3 times the rated torque, and the overload capacity is excellent. It is especially suitable for high starting torque. Mechanical equipment with torque and overload capacity.

YTM/YHP/YMPS high-voltage asynchronous motor for coal mill

YTM, YHP, YMPS The motor torque-speed characteristic curve is relatively flat, the starting torque, the maximum torque and the minimum torque are all higher than 3 times the rated torque, and the overload capacity is excellent. It is especially suitable for high starting torque. Mechanical equipment with torque and overload capacity.

Variable Frequency Three-phase Asynchronous Motor

YPKK series variable frequency three-phase asynchronous motor is the new product series newly designed by our company on the basis of Y, YKK series high-voltage squirrel cage motor.

Variable Frequency Three-phase Asynchronous Motor

YPKK series variable frequency three-phase asynchronous motor is the new product series newly designed by our company on the basis of Y, YKK series high-voltage squirrel cage motor.

Large Squirrel Cage Motor

YTM, YHP, YMPS series coal mill special three-phase asynchronous high-voltage motor is a closed cage rotor motor.

Large Squirrel Cage Motor

YTM, YHP, YMPS series coal mill special three-phase asynchronous high-voltage motor is a closed cage rotor motor.

High Voltage Induction Motor

Y2 series (10KV) high-voltage motor is usually Class F, and the temperature rise limit of the motor for indirect cooling of the air is:

High Voltage Induction Motor

Y2 series (10KV) high-voltage motor is usually Class F, and the temperature rise limit of the motor for indirect cooling of the air is:

High Voltage Induction Motor

Y2 series (6KV) high-voltage induction three-phase asynchronous motor is based on the experience of our company for many years of motor manufacturing.

High Voltage Induction Motor

Y2 series (6KV) high-voltage induction three-phase asynchronous motor is based on the experience of our company for many years of motor manufacturing.

High Voltage Squirrel Cage Induction Motor

YKK series squirrel cage high-voltage three-phase asynchronous Induction motor is a cage-type asynchronous motor with closed air-to-air cooler. This series of motors is rated IP44 or IP54 and the cooling method is IC611.

High Voltage Squirrel Cage Induction Motor

YKK series squirrel cage high-voltage three-phase asynchronous Induction motor is a cage-type asynchronous motor with closed air-to-air cooler. This series of motors is rated IP44 or IP54 and the cooling method is IC611.

Large High Voltage Motor

YXKK series high-efficiency high-voltage three-phase asynchronous motor is an optimized series of products developed on the basis of absorbing foreign advanced technology and combining with the company's high-voltage motor design and manufacturing experience.

Large High Voltage Motor

YXKK series high-efficiency high-voltage three-phase asynchronous motor is an optimized series of products developed on the basis of absorbing foreign advanced technology and combining with the company's high-voltage motor design and manufacturing experience.

High Voltage Motor Supplier

Y series (10KV)high-voltage motor adopts box structure, and the motor base is welded by steel plate, which is light in weight and good in rigidity.

High Voltage Motor Supplier

Y series (10KV)high-voltage motor adopts box structure, and the motor base is welded by steel plate, which is light in weight and good in rigidity.

High Voltage Motor for Sale

Y series (6KV) high-voltage squirrel cage motor allows direct start at full pressure.

High Voltage Motor for Sale

Y series (6KV) high-voltage squirrel cage motor allows direct start at full pressure.

Hot Selling High Voltage Motor

YKS series (6KV) high-voltage motor is a cage-type rotor asynchronous motor with air-water cooler.

Hot Selling High Voltage Motor

YKS series (6KV) high-voltage motor is a cage-type rotor asynchronous motor with air-water cooler.

Squirrel Cage High Voltage Motor

YKK series squirrel cage high-voltage three-phase asynchronous motor is a cage-type asynchronous motor with closed air-to-air cooler.

Squirrel Cage High Voltage Motor

YKK series squirrel cage high-voltage three-phase asynchronous motor is a cage-type asynchronous motor with closed air-to-air cooler.

High Quality High Voltage Motor

YKS series (10KV) high-voltage squirrel cage motor adopts the internationally popular box structure.

High Quality High Voltage Motor

YKS series (10KV) high-voltage squirrel cage motor adopts the internationally popular box structure.

Copyright © ZCL Electric Motor Technology Co., Ltd. All Rights Reserved | Sitemap | Powered by