Brand: ZCL

Product Origin: China

Delivery Time: 30-65 days

Supply Capacity: 200 units/month

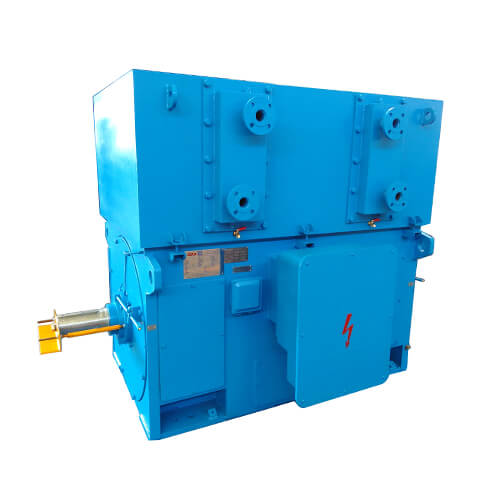

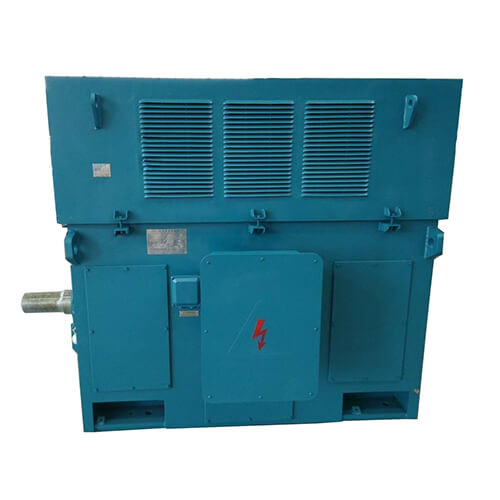

Y2 series (6KV) high-voltage induction three-phase asynchronous motor is based on the experience of our company for many years of motor manufacturing. It uses large-scale finite element analysis software to analyze the field of the motor's structure field, electromagnetic field, temperature field and fluid field level. At the same time, a new generation of high-efficiency, energy-saving and environmentally-friendly motors designed and manufactured using the principle of dual-cycle cooling ventilation system. It has the advantages of small size, light weight, compact structure, beautiful appearance and smooth lines.

The Y2 series (6KV) high-voltage induction motor has two independent cooling air paths: the inner cooling air path and the outer cooling air path. Most of the heat generated by the loss is transmitted from the stator core to the base and then taken away by the external cooling air. The rest of the heat loss is transmitted from the inner cooling circuit to the base and then taken away by the external cooling air.

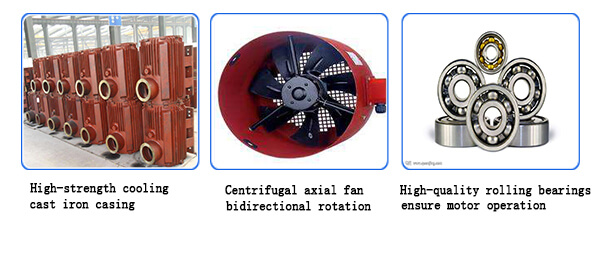

The Y2 high-voltage induction motor base adopts an orthogonally distributed full-heating cast iron base. The fins are combined with unequal distance distribution and non-concentric circles, and four axial air passages are arranged in the 45-degree direction. As the frame is waisted, external cooling air is blown more efficiently from the non-drive end to the drive end along the heat sink for optimum cooling. The junction box is installed at the air passage above the motor side, and does not affect the heat dissipation and the flow of cooling air. The inner surface of the base around the winding end of the stator is provided with a heat absorbing rib. The rib structure of the radiator with a large enough heat dissipation area ensures a strong heat dissipation capability.

Two hoisting rings that can be adjusted at any angle are installed diagonally on the air passage of the motor to facilitate motor lifting.

The drive end and the non-drive end of the motor have the same structure, and there are heat dissipation ribs inside and outside to increase the rigidity and heat dissipation capability of the end cover. The high-strength cast iron base and end cap ensure high stability of the motor.

Y2 series (6KV) compact high-voltage induction motor, its power level, electrical performance and installation dimensions are in line with the international IEC34-1 standard. This series of high-voltage induction motor housings are IP54 or IP55, and the cooling method is IC411. The motor can produce motors of various specifications of 6.6kV, 3kV and 3.3kV according to customer requirements. This series of products is small in size, light in weight, compact in structure, high in efficiency and low in noise, meeting customer's environmental requirements. The motor defaults to the IMB3 installation method, and can also produce motors with IMB35 and IMV1 installation sizes according to customer requirements.

Y2 series (6KV) high-voltage induction motor is suitable for dragging compressors, fans, pumps, crushers, metal cutting machine tools, coal mills, transportation machinery, etc. It is also used in mining industry, machinery industry, petrochemical industry and other industrial and mining industries. The enterprise is used as the prime mover. Motors used to drive blowers, coal mills, crushers, and rolling mills should provide relevant technical information when ordering to ensure reliable operation of the motor.

Product Parameters

Center high range: H355-H560

Power range: 185KW-1600KV

Voltage: 3KV/3.3KV/6KV/6.6KV

Rated frequency: 50HZ/60HZ

Protection level: IP44/IP54/IP55

Cooling method: IC411

Insulation class: Class F

Working system: S1

Wiring method: Y

Field operating conditions:

(1) Normal motor operating location does not exceed 1000M

(2) The maximum ambient air temperature does not exceed 40 ° C

(3) The minimum ambient air temperature is not lower than -20 °C, and the minimum ambient air temperature of the motor with sliding bearing should not be lower than 0 °C.

Feature of Product

Y2 high-voltage compact three-phase asynchronous motor is based on the experience of our company for many years of motor manufacturing. It uses large-scale finite element analysis software to analyze the field, electromagnetic field, temperature field and fluid field level of the motor. At the same time, a new generation of high-efficiency, energy-saving and environmentally-friendly motors designed and manufactured using the principle of dual-cycle cooling ventilation system. It has the advantages of small size, light weight, compact structure, beautiful appearance and smooth lines.

The motor base adopts an orthogonally distributed full-heating cast iron base. The heat sinks are combined with unequal distance distribution and non-concentric circles, and four axial air passages are arranged in the 45-degree direction.

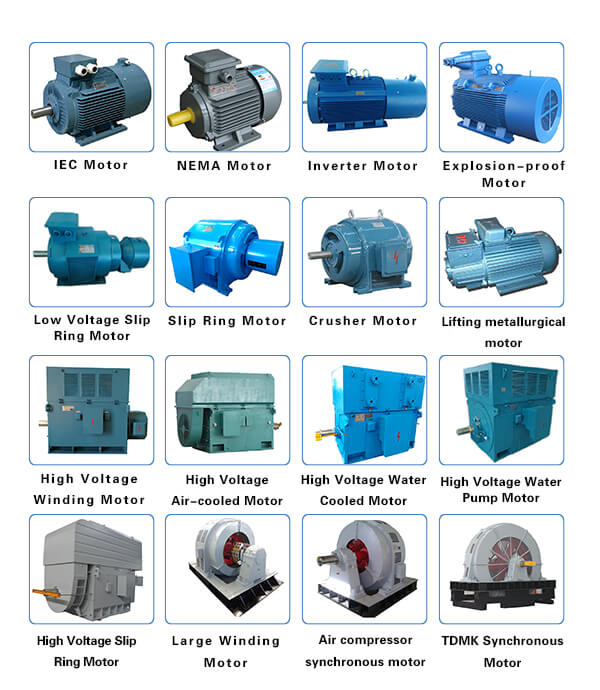

More Product

There are many types of motor products manufactured and sold by our company. The main products are high- and low-voltage three-phase asynchronous motors. The motor structure types include squirrel-cage type and winding type. Among them, high-voltage synchronous motors mainly support air compressors and mine ball mill equipment. use. We adhere to the service tenet of "focus on products, service with heart" and provide high-quality motor products to customers.

Equipment Capacity

The company has large-scale laboratory, intelligent CNC winding machine, CNC rising machine, automatic wrapping machine, VPI high pressure vacuum immersion system, large-scale dipping paint drying furnace, 60 tons test platform, large vertical car, milling machine, grinding machine, Each type of dynamic balancing machine, double-feedback test and detection system with 6MW (12MW) motor and other motor production professional equipment more than 500 sets, sound mechanical equipment processing capacity, to lay a good foundation for customers to improve good quality motor products.

Product Use

The motor products manufactured and sold by our company are used in many industries, such as electric power, mining, steel metallurgy, petrochemical, water conservancy, transportation, building materials and many other industries. The equipment for the motor is pump, machine tool, fan, mill, crusher, rolling mill, compressor and many other industrial equipment.

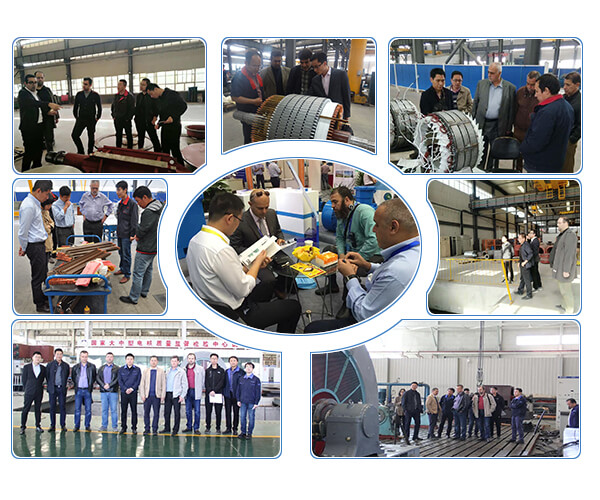

Customer Visit

The company insists on providing high-quality motor products and services to users, and has won high praise from many domestic and foreign customers. The company will receive many foreign merchants to visit our factory every year, and establish a good cooperative relationship through on-site inspection of our factory. Our company always welcomes customers to visit our factory.

High Voltage Motor for Sale

Y series (6KV) high-voltage squirrel cage motor allows direct start at full pressure.

High Voltage Motor for Sale

Y series (6KV) high-voltage squirrel cage motor allows direct start at full pressure.

High Quality High Voltage Motor

YKS series (10KV) high-voltage squirrel cage motor adopts the internationally popular box structure.

High Quality High Voltage Motor

YKS series (10KV) high-voltage squirrel cage motor adopts the internationally popular box structure.

Large Electric Motor

Customized OEM for large electric motors, low voltage and high voltage squirrel cage induction motors, low voltage and high voltage winding rotor slip ring motors, and large synchronous excitation motors.

Large Electric Motor

Customized OEM for large electric motors, low voltage and high voltage squirrel cage induction motors, low voltage and high voltage winding rotor slip ring motors, and large synchronous excitation motors.

Hot Selling High Voltage Motor

YKS series (6KV) high-voltage motor is a cage-type rotor asynchronous motor with air-water cooler.

Hot Selling High Voltage Motor

YKS series (6KV) high-voltage motor is a cage-type rotor asynchronous motor with air-water cooler.

High Voltage Motor Supplier

Y series (10KV)high-voltage motor adopts box structure, and the motor base is welded by steel plate, which is light in weight and good in rigidity.

High Voltage Motor Supplier

Y series (10KV)high-voltage motor adopts box structure, and the motor base is welded by steel plate, which is light in weight and good in rigidity.

Squirrel Cage High Voltage Motor

YKK series squirrel cage high-voltage three-phase asynchronous motor is a cage-type asynchronous motor with closed air-to-air cooler.

Squirrel Cage High Voltage Motor

YKK series squirrel cage high-voltage three-phase asynchronous motor is a cage-type asynchronous motor with closed air-to-air cooler.

YTM/YHP/YMPS high-voltage asynchronous motor for coal mill

YTM, YHP, YMPS The motor torque-speed characteristic curve is relatively flat, the starting torque, the maximum torque and the minimum torque are all higher than 3 times the rated torque, and the overload capacity is excellent. It is especially suitable for high starting torque. Mechanical equipment with torque and overload capacity.

YTM/YHP/YMPS high-voltage asynchronous motor for coal mill

YTM, YHP, YMPS The motor torque-speed characteristic curve is relatively flat, the starting torque, the maximum torque and the minimum torque are all higher than 3 times the rated torque, and the overload capacity is excellent. It is especially suitable for high starting torque. Mechanical equipment with torque and overload capacity.

Large Squirrel Cage Motor

YTM, YHP, YMPS series coal mill special three-phase asynchronous high-voltage motor is a closed cage rotor motor.

Large Squirrel Cage Motor

YTM, YHP, YMPS series coal mill special three-phase asynchronous high-voltage motor is a closed cage rotor motor.

High Voltage Squirrel Cage Induction Motor

YKK series squirrel cage high-voltage three-phase asynchronous Induction motor is a cage-type asynchronous motor with closed air-to-air cooler. This series of motors is rated IP44 or IP54 and the cooling method is IC611.

High Voltage Squirrel Cage Induction Motor

YKK series squirrel cage high-voltage three-phase asynchronous Induction motor is a cage-type asynchronous motor with closed air-to-air cooler. This series of motors is rated IP44 or IP54 and the cooling method is IC611.

Variable Frequency Three-phase Asynchronous Motor

YPKK series variable frequency three-phase asynchronous motor is the new product series newly designed by our company on the basis of Y, YKK series high-voltage squirrel cage motor.

Variable Frequency Three-phase Asynchronous Motor

YPKK series variable frequency three-phase asynchronous motor is the new product series newly designed by our company on the basis of Y, YKK series high-voltage squirrel cage motor.

High Voltage Induction Motor

Y2 series (10KV) high-voltage motor is usually Class F, and the temperature rise limit of the motor for indirect cooling of the air is:

High Voltage Induction Motor

Y2 series (10KV) high-voltage motor is usually Class F, and the temperature rise limit of the motor for indirect cooling of the air is:

High Voltage Rib Cooled Motors

High Voltage Ribbed Cold Motor is a high-performance cast iron casing motor. The motor is a fully enclosed air-cooled

(TEFC) motor.

High Voltage Rib Cooled Motors

High Voltage Ribbed Cold Motor is a high-performance cast iron casing motor. The motor is a fully enclosed air-cooled

(TEFC) motor.

Copyright © ZCL Electric Motor Technology Co., Ltd. All Rights Reserved | Sitemap | Powered by