Brand: ZCL

Product Origin: China

Delivery Time: 40-75 days

Supply Capacity: 500 units/month

The Wound Rotor Motor is a high-pressure slip ring motor developed and manufactured by our company for many years. This type of motor adopts box structure. The frame is made of steel plate welded box structure, which is light in weight and good in rigidity. There are windows on both sides and top of the frame. Holes, can be installed with a protective cover or cover, after removing the protective cover or cover, you can observe and touch the inside of the motor to facilitate the maintenance and repair of the motor.

The rotor of the wound rotor motor adopts a sliding-in external press-fit structure. The stator winding is made of Class F insulation material, and the ends are reliably fixed and bundled. During the manufacturing process, multiple turns of the pulse voltage test and the ground pressure test are carried out. And vacuum pressure impregnation solventless paint process (VPI) treatment, therefore, the motor's insulation performance is excellent and reliable, mechanical strength is good, moisture resistance is strong. The wound rotor is treated with Class F insulation and vacuum pressure impregnation solventless paint process (VPI). The rotor weld head and the wiring are all insulated. The bearing has two types of rolling bearing and sliding bearing. According to the motor power and speed, the basic form of protection is IP54. If the motor has a high degree of protection, the protection level of the bearing will also increase.

The main outlet box of the wound rotor motor is IP54 protection grade. It is usually installed on the right side of the motor (facing the motor shaft extension). It can also be installed on the left side of the motor according to the order. There is a separate grounding inside the main outlet box. Terminal.

The wound rotor motor is a slip ring three-phase asynchronous motor. The power rating, installation dimensions and electrical performance of this type of motor comply with the relevant IEC standards. The basic installation method of the motor is the horizontal bottom angle (IMB3), the working system is the continuous working system (S1), and the wound rotor is made of Class F insulation material.

The winding rotor motor has two types of bearings: rolling bearing and sliding bearing, depending on the motor power and speed. The rated frequency of the motor's power supply is 50Hz, the rated voltage is 6000V/10000V, and the basic type of protection is IP54. The motor slip ring housing can be protected to IP22 or IP23. Other voltage, frequency and degree of protection motors are also available upon request.

Wound rotor motors can be used to drive a variety of different machinery, such as compressors, pumps, crushers, cutting machine tools, transportation machinery and other mechanical equipment, in mining, machinery industry, petrochemical industry, power plants and other industrial and mining enterprises. Used as the prime mover. The motor used to drive the blower, coal mill, rolling mill and winch should indicate the purpose and technical requirements when ordering, and adopt special design to ensure reliable operation.

Product Parameters

Center height range: H355 ~ 1000mm

Power range: 220kW ~ 10000kW

Number of poles: 2/4/6/8/10/12

Rated voltage: 3000V/6000V/6600V/10000V/11000V

Rated frequency: 50HZ/60HZ

Protection level: IP54 or IP55

Insulation class: F

Work system: S1 (continuous)

Cooling method: IC611/IC616

Installation form: IMB3

Motor connection: Y (three outlet terminals in the junction box, the junction box from the extension of the spindle is located on the right side of the base)

Altitude: no more than 1000m

This type of motor is suitable for use in environments where the ambient air temperature does not exceed 40 ° C and there is no serious dust, the minimum ambient air temperature is -15 ° C, and there is no corrosive and explosive gas in the air (which can also be made into a damp heat or high-altitude motor).

Feature of Product

The wound rotor motor is a slip-surrounding three-phase asynchronous motor, which can increase the starting torque at a small starting current. The motor is suitable for applications where the capacity of the feeder line is insufficient to start the squirrel-cage rotor, the starting time is long, the starting is frequent, and the small-range speed regulation is required. This series of motors has the advantages of high efficiency, energy saving, low noise, low vibration, light weight, reliable performance, convenient installation and maintenance.

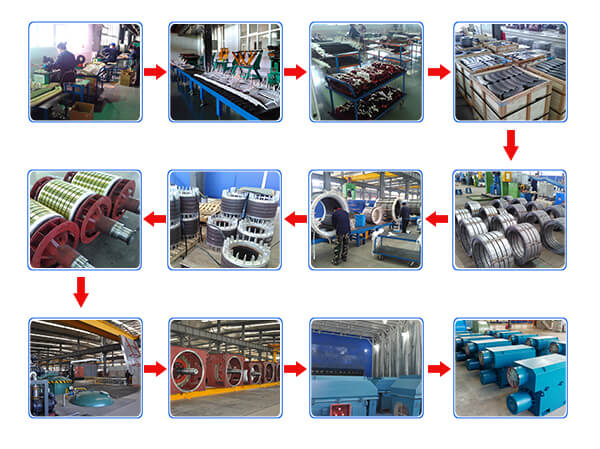

Factory Glimpse

Our company's motor manufacturing factory adheres to the concept of green, efficient and energy-saving production service, pays attention to the harmonious development of internal and external environment, builds environmentally friendly motor manufacturing enterprises, strictly implements motor standard process, and selects high-quality energy-saving materials to ensure the quality of motor products.

Equipment Capacity

The company has large-scale laboratory, intelligent CNC winding machine, CNC rising machine, automatic wrapping machine, VPI high pressure vacuum immersion system, large-scale dipping paint drying furnace, 60 tons test platform, large vertical car, milling machine, grinding machine, Each type of dynamic balancing machine, double-feedback test and detection system with 6MW (12MW) motor and other motor production professional equipment more than 500 sets, sound mechanical equipment processing capacity, to lay a good foundation for customers to improve good quality motor products.

Main Process Flow of the Motor

Motor stator: casing processing → punching press → iron core seating → coil making → weaving → dipping paint drying

Electronic rotor: blank shaft processing → iron core press installation → iron core cast aluminum → rotor string shaft → weave → dipping paint drying → dynamic balance

Motor assembly: stator rotor assembly → machine test → motor appearance coloring → packaging storage

Contact Us

If you are interested in our products motor, please feel free to contact us! Thank you very much!

Shijiazhuang ZCL Electric Motor Technology Co., Ltd.

Add.: Industrial Zone, Zhangjiazhuang Town, Airport Road, gaocheng District, Shijiazhuang, Hebei, China

Tel./Fax: 86-13931192007/ 86-311-89246924

Skype:+86-13931192007

QQ: 568151260

Welcome to visit our factory!

E-mail: zclgroup@zcl-group.com

JR slip ring motor for ball mill

JR ball mill motor adopts rotor string resistance full-voltage start-up, which has the advantages of small starting current, large starting torque, high efficiency, low noise, low vibration, good ventilation performance, reliable operation, convenient installation and maintenance.

JR slip ring motor for ball mill

JR ball mill motor adopts rotor string resistance full-voltage start-up, which has the advantages of small starting current, large starting torque, high efficiency, low noise, low vibration, good ventilation performance, reliable operation, convenient installation and maintenance.

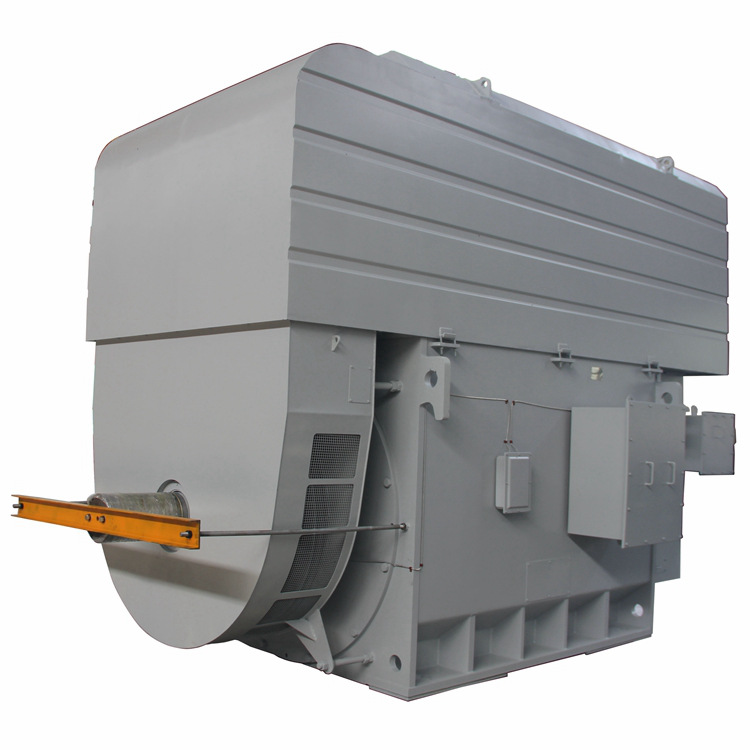

High Quality Slip Ring Motor

The high-quality slip ring motor adopts box-type structure.

High Quality Slip Ring Motor

The high-quality slip ring motor adopts box-type structure.

Slip Ring Motor

The slip ring motor is a wound high-voltage asynchronous motor (frame size 355-1000).

Slip Ring Motor

The slip ring motor is a wound high-voltage asynchronous motor (frame size 355-1000).

6kv Slip Ring Motor

6KV slip ring motor is a high-voltage wound rotor three-phase asynchronous motor developed and manufactured by our company for many years.

6kv Slip Ring Motor

6KV slip ring motor is a high-voltage wound rotor three-phase asynchronous motor developed and manufactured by our company for many years.

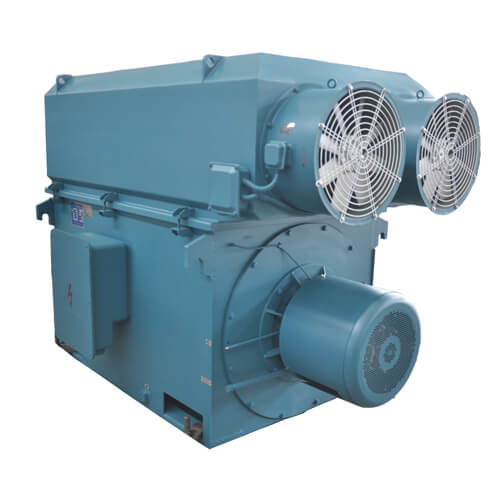

High Voltage Slip Ring Induction Motor

YRKK series HV slip ring induction motors are used in the motors of heavy-duty starting equipment such as ball mills, rolling mills, sugar mills, crushers, etc.

High Voltage Slip Ring Induction Motor

YRKK series HV slip ring induction motors are used in the motors of heavy-duty starting equipment such as ball mills, rolling mills, sugar mills, crushers, etc.

High Voltage Wound Rotor Induction Motor

YRKS series High Voltage Wound Rotor Induction Motor are used in the motors of heavy-duty starting equipment such as ball mills, rolling mills, sugar mills, crushers, etc.

High Voltage Wound Rotor Induction Motor

YRKS series High Voltage Wound Rotor Induction Motor are used in the motors of heavy-duty starting equipment such as ball mills, rolling mills, sugar mills, crushers, etc.

Slip Ring Induction Motor

The mechanical strength of the slip ring induction motor winding is high, which improves the insulation level of the motor. The slip ring and carbon brush device of the motor are placed outside the end cover, which can effectively prevent carbon dust from contaminating the coil. At the same time, it is also easy to replace the repair.

Slip Ring Induction Motor

The mechanical strength of the slip ring induction motor winding is high, which improves the insulation level of the motor. The slip ring and carbon brush device of the motor are placed outside the end cover, which can effectively prevent carbon dust from contaminating the coil. At the same time, it is also easy to replace the repair.

Slip Ring Motor

YRKK series motors are slip-surrounding three-phase asynchronous motors, which can increase the starting torque at a small starting current.

Slip Ring Motor

YRKK series motors are slip-surrounding three-phase asynchronous motors, which can increase the starting torque at a small starting current.

Slip Ring Motor Suppliers

The slip ring motor is a wound three-phase asynchronous motor.

Slip Ring Motor Suppliers

The slip ring motor is a wound three-phase asynchronous motor.

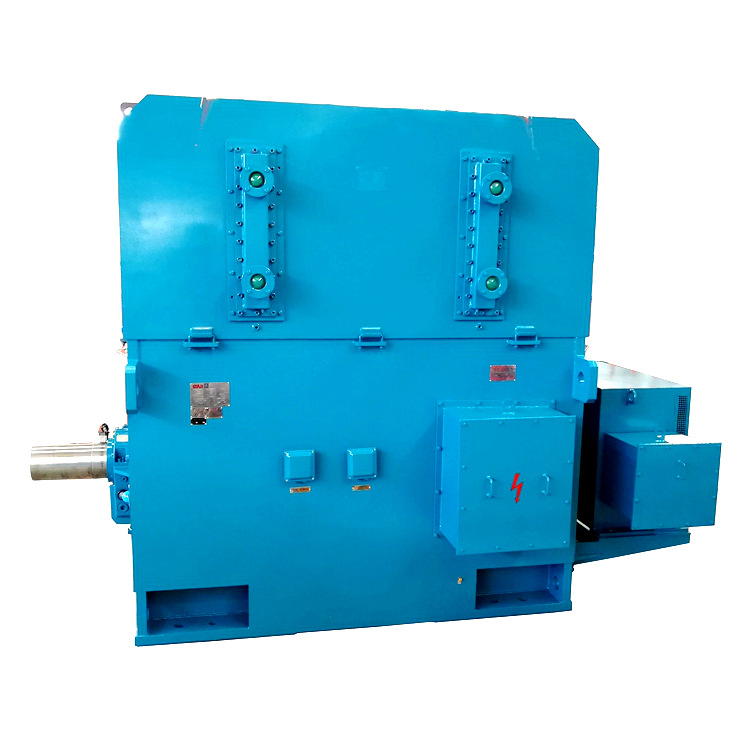

Heavy Duty High Voltage Slip Ring Motor

YR series heavy-duty high-voltage slip ring motor (open type) is a steel plate welding machine base, horizontal structure large-winding three-phase asynchronous motor.

Heavy Duty High Voltage Slip Ring Motor

YR series heavy-duty high-voltage slip ring motor (open type) is a steel plate welding machine base, horizontal structure large-winding three-phase asynchronous motor.

Asynchronous Slip Ring Motor

The asynchronous slip ring motor is a high voltage wound three-phase asynchronous motor.

Asynchronous Slip Ring Motor

The asynchronous slip ring motor is a high voltage wound three-phase asynchronous motor.

High-voltage Wound Rotor Slip Ring Motor

The high-voltage wound rotor slip ring motor is a high-voltage three-phase asynchronous motor developed and manufactured by our company for many years.

High-voltage Wound Rotor Slip Ring Motor

The high-voltage wound rotor slip ring motor is a high-voltage three-phase asynchronous motor developed and manufactured by our company for many years.

Copyright © ZCL Electric Motor Technology Co., Ltd. All Rights Reserved | Sitemap | Powered by