Brand: ZCL

Product Origin: china

Delivery Time: 30-50 days

Supply capacity: 300 per month

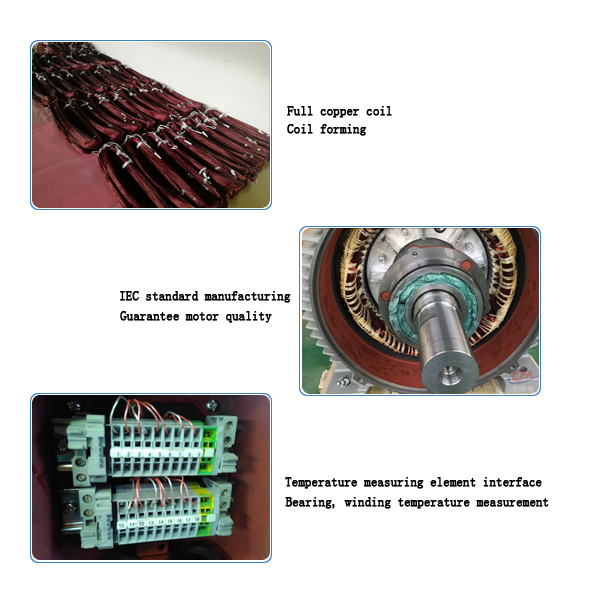

The low-voltage variable frequency motor has the characteristics of wide speed regulation range, low vibration and low noise. The motor adopts the squirrel-cage structure, which is reliable in operation and convenient in maintenance. The installation dimensions and power levels are in accordance with the IEC standard, which is consistent with the corresponding Y series low-voltage motors. Interchangeability and versatility.

The low-voltage variable frequency speed control motor is equipped with an independent cooling fan to ensure that the motor has good cooling effect at different speeds. This series of motors outputs constant torque when operating from 5 (3) to 50 Hz, and outputs constant power when operating from 50 to 100 Hz.

The low-voltage variable frequency motor can be used with many inverters, and controlled by the inverter to achieve the speed under different conditions.

Frame number range: 315-560

Power range: 200kW-1500kW

Frequency: 50/60Hz

Number of levels: 2/4/6/8/10

Working system: S1

Protection level: IP54/IP55

Insulation class: F

Cooling method: IC416

Ambient temperature: -15 ° C ~ 40 ° C

Altitude: no more than 1000M

Voltage: 220V, 380V, 660V, 220/380V, 380/660V

Working mode: continuous (S1), allowing full pressure starting.

Frequency conversion range: 5Hz ~ 50Hz constant torque operation

50Hz ~ 100Hz constant power operation

Wiring method: 55KW and below for Y connection, above 55KW for △ connection

Note: If there are special requirements for frequency, voltage, etc., it can be submitted at the time of ordering!

(1) High efficiency and remarkable energy saving;

(2) Speed regulation smoothing can stepless speed regulation in the range of 5-100HZ.

(3) When the low frequency starts, the torque is less affected by the load;

(4) The starting current is small, no additional starting equipment is required;

(5) Small in size, light in weight, and the same size as the Y series;

(6) An axial fan is installed in the hood, which has good cooling effect at various speeds;

(7) Wide application range, constant torque operation below 50HZ, constant power operation above 50HZ;

(8) Compared with the electromagnetic speed regulating motor, the structure is simple, the use is reliable, and the maintenance is convenient.

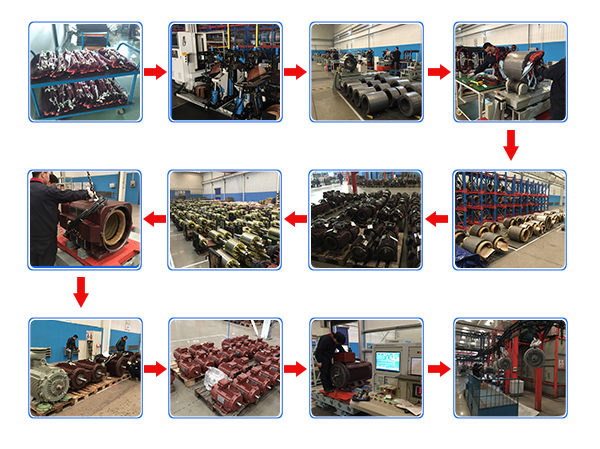

Main process flow of the motor

Motor stator: casing processing → punching press → iron core seating → coil making → weaving → dipping paint drying

Electronic rotor: blank shaft processing → iron core press installation → iron core cast aluminum → rotor string shaft → weave → dipping paint drying → dynamic balance

Motor assembly: stator rotor assembly → machine test → motor appearance coloring → packaging storage

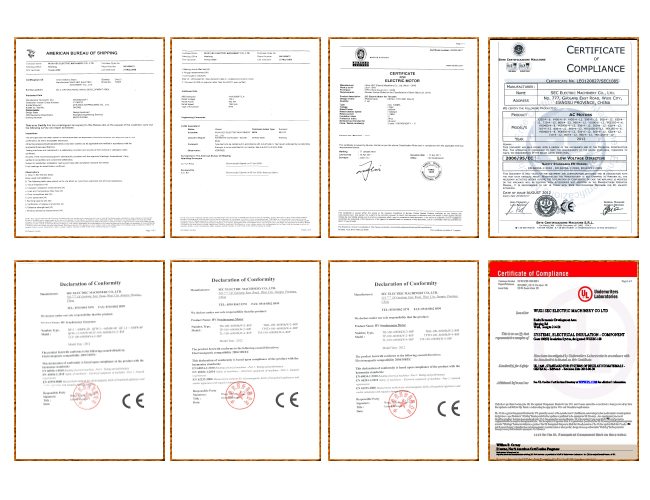

The motor products manufactured by our company have obtained the ISO9001 quality management management system certification, passed the CCC/COC, China energy-saving product certification, and passed the certification certificates of CE/UL/IRIS/CAS and other European and American countries. The company strictly improves the quality and efficient motor products and services for users in strict accordance with the requirements of relevant product standards.

Our company's motor manufacturing factory adheres to the concept of green, efficient and energy-saving production service, pays attention to the harmonious development of internal and external environment, builds environmentally friendly motor manufacturing enterprises, strictly implements motor standard process, and selects high-quality energy-saving materials to ensure the quality of motor products.

1. Professional motor manufacturing service provider;

2. Sound product quality management and certification system;

3. Have a professional sales and technical service team;

4. The motor has perfect process and strong mechanical processing capability;

5. High standard product technical service system;

6, good faith and mutual benefit, good credit guarantee.

Three-phase Asynchronous Motor

Cast iron casing, durable, the shell is made of high-strength steel tool casting, and the manufacturing process is excellent.

Three-phase Asynchronous Motor

Cast iron casing, durable, the shell is made of high-strength steel tool casting, and the manufacturing process is excellent.

IEC Motor Manufacturer

International Electrotechnical Commission(IEC).Founded in 1906, it is the world's first international electrical standardization organization responsible for international standardization in electrical engineering and electronic engineering.

IEC Motor Manufacturer

International Electrotechnical Commission(IEC).Founded in 1906, it is the world's first international electrical standardization organization responsible for international standardization in electrical engineering and electronic engineering.

NEMA Motor

NEMA series ultra-high-efficiency three-phase asynchronous motor has the advantages of simple structure, flexible control, high system efficiency and remarkable energy saving effect.

NEMA Motor

NEMA series ultra-high-efficiency three-phase asynchronous motor has the advantages of simple structure, flexible control, high system efficiency and remarkable energy saving effect.

Y Large High Voltage Water Pump, Fan Squirrel Cage Motor

Y series high-voltage water pump and fan squirrel cage motor adopt box type structure, and the motor base is welded by steel plate, which is light in weight and good in rigidity.

Y Large High Voltage Water Pump, Fan Squirrel Cage Motor

Y series high-voltage water pump and fan squirrel cage motor adopt box type structure, and the motor base is welded by steel plate, which is light in weight and good in rigidity.

Asynchronous Motor

YE3 ultra-high efficiency three-phase asynchronous motor adopts high magnetic permeability and low loss cold-rolled non-oriented silicon steel sheet, which is characterized by ultra-high efficiency, energy saving, low vibration, low noise, reliable performance and convenient installation and maintenance.

Asynchronous Motor

YE3 ultra-high efficiency three-phase asynchronous motor adopts high magnetic permeability and low loss cold-rolled non-oriented silicon steel sheet, which is characterized by ultra-high efficiency, energy saving, low vibration, low noise, reliable performance and convenient installation and maintenance.

AC Motors

IEC standard electric motors, energy efficiency standards IE2, IE3, IE4, fully enclosed TEFC.

AC Motors

IEC standard electric motors, energy efficiency standards IE2, IE3, IE4, fully enclosed TEFC.

IE2 Motor

IE2 motor is a general-purpose fully enclosed fan-cooled squirrel-cage three-phase asynchronous motor, and its efficiency reaches China GB18613-2012 Level 3 energy efficiency or IEC60034-30 standard level 2 energy efficiency.

IE2 Motor

IE2 motor is a general-purpose fully enclosed fan-cooled squirrel-cage three-phase asynchronous motor, and its efficiency reaches China GB18613-2012 Level 3 energy efficiency or IEC60034-30 standard level 2 energy efficiency.

High Efficiency Motor

High-efficiency motors are more efficient motors whose efficiency should meet the relevant energy efficiency rating requirements.

High Efficiency Motor

High-efficiency motors are more efficient motors whose efficiency should meet the relevant energy efficiency rating requirements.

IE3 Motor

IE3 ultra-high efficiency motor adopts high magnetic permeability and low loss cold-rolled non-oriented silicon steel sheet, which is characterized by ultra-high efficiency, energy saving, low vibration, low noise, reliable performance and convenient installation and maintenance.

IE3 Motor

IE3 ultra-high efficiency motor adopts high magnetic permeability and low loss cold-rolled non-oriented silicon steel sheet, which is characterized by ultra-high efficiency, energy saving, low vibration, low noise, reliable performance and convenient installation and maintenance.

IEC Motor

IEC motor series motors are characterized by high efficiency, energy saving, high quality, low vibration, low noise, long life, high reliability, convenient maintenance and large starting torque.

IEC Motor

IEC motor series motors are characterized by high efficiency, energy saving, high quality, low vibration, low noise, long life, high reliability, convenient maintenance and large starting torque.

NEMA Motor Manufacturers

NEMA high-efficiency three-phase asynchronous motor is a fully enclosed self-fan-cooled motor.

NEMA Motor Manufacturers

NEMA high-efficiency three-phase asynchronous motor is a fully enclosed self-fan-cooled motor.

Induction Motor

Induction motor, also known as asynchronous motor, that is, the rotor is placed in a rotating magnetic field, under the action of a rotating magnetic field, a rotational moment is obtained, and thus the rotor rotates.

Induction Motor

Induction motor, also known as asynchronous motor, that is, the rotor is placed in a rotating magnetic field, under the action of a rotating magnetic field, a rotational moment is obtained, and thus the rotor rotates.

Copyright © ZCL Electric Motor Technology Co., Ltd. All Rights Reserved | Sitemap | Powered by