High efficiency motors are more efficient motors whose efficiency should meet the relevant energy efficiency rating requirements. High Efficiency Motors take measures from design, materials and processes, such as reasonable positioning, rotor slot number, fan parameters and sinusoidal windings to reduce losses, and efficiency can be increased by 2%-8%, with an average increase of 4%.

(1) High efficiency, IE2 is 3% higher than IE1, and IE3 is about 5% higher than IE1.

(2) More energy-saving materials are needed. IE2 costs 25% to 30% more than IE1 motors, and IE3 costs 40% to 60% more than IE1 motors.

(3) Due to the lower operating temperature, the motor has a longer life and can reduce maintenance costs.

(4) The starting current is larger under typical design conditions.

(5) The rotor inertia is large.

(6) High speed at rated load, small slip rate

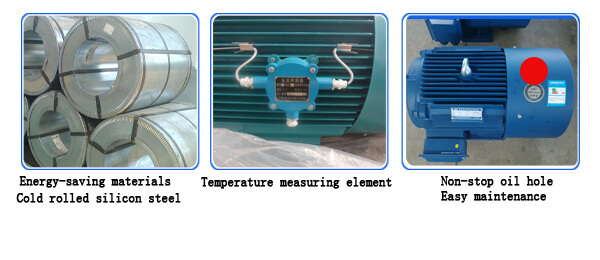

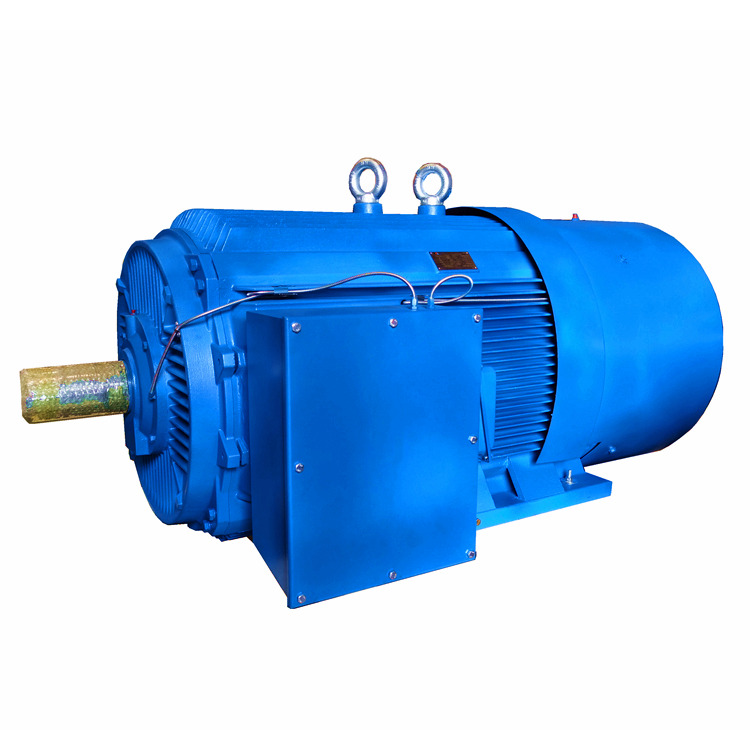

YE2 series high efficiency motors are high-efficiency motors with cold-rolled silicon steel as the magnetic conductive material. The YE2 motor is a fully enclosed self-fan cooled squirrel-cage high-efficiency three-phase asynchronous motor. The efficiency index of this series of motors reaches the level 3 energy efficiency rating in China GB18613-2012 "Small and Medium-sized Three-Phase Asynchronous Motors Limited Value and Energy Efficiency Rating". YE2 high efficiency motor has high efficiency and various performance indicators have reached the international advanced level. The motor is used to drive long-running loads such as fans and pumps, which is energy efficient and saves energy.

The installation size and power level of YE2 high-efficiency three-phase asynchronous motor conforms to the International Electrotechnical Commission IEC72-1 standard. The center high H160 and above motor is equipped with non-stop injection oil discharge device, and space for installing the thermistor and moisture-proof heating belt is reserved. It is convenient for users to choose. The motor stator adopts Class F insulation, but the temperature rise is evaluated according to 80K, the motor temperature rise is low, and the service life is long; the rotor adopts the cast aluminum process, and the running reliability is high.

Frame number range: 80-355

Power range: 0.75kW-315kW

Frequency: 50/60Hz

Number of levels: 2/4/6/8

Energy efficiency rating: IE2

Working system: S1

Protection level: IP55/IP56

Insulation class: F

Cooling method: IC411

Ambient temperature: varies with the seasons, but does not exceed 40•C.

Altitude: no more than 1000M

Voltage: 220V, 380V, 660V, 220/380V, 380/660V

Working mode: continuous (S1), allowing full pressure starting.

Wiring method: rated power ≤ 3KW motor is Y wiring mode, rated power ≥ 4KW motor is △ wiring mode.

Note: If there are special requirements for frequency, voltage, etc., it can be submitted at the time of ordering!

Applications: pumps, reducers, compressors

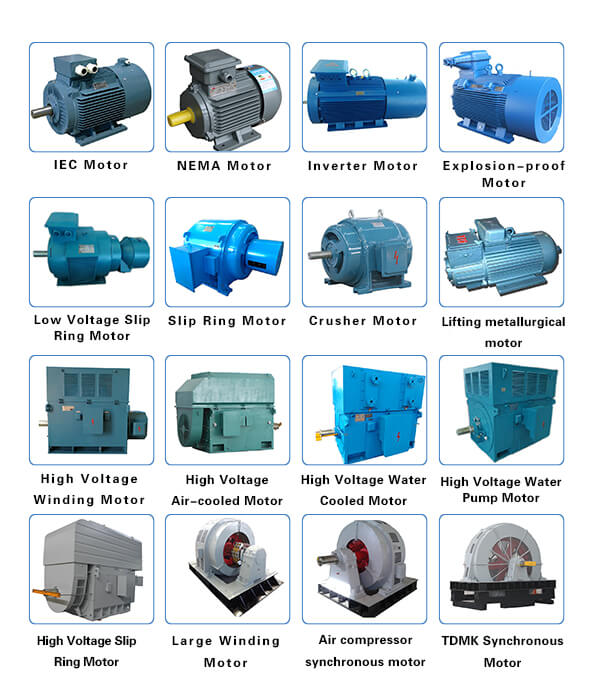

There are many types of motor products manufactured and sold by our company. The main products are high- and low-voltage three-phase asynchronous motors. The motor structure types include squirrel-cage type and winding type. Among them, high-voltage synchronous motors mainly support air compressors and mine ball mill equipment. use. We adhere to the service tenet of "focus on products, service with heart" and provide high-quality motor products to customers.

The company has large-scale laboratory, intelligent CNC winding machine, CNC rising machine, automatic wrapping machine, VPI high pressure vacuum immersion system, large-scale dipping paint drying furnace, 60 tons test platform, large vertical car, milling machine, grinding machine, Each type of dynamic balancing machine, double-feedback test and detection system with 6MW (12MW) motor and other motor production professional equipment more than 500 sets, sound mechanical equipment processing capacity, to lay a good foundation for customers to improve good quality motor products.

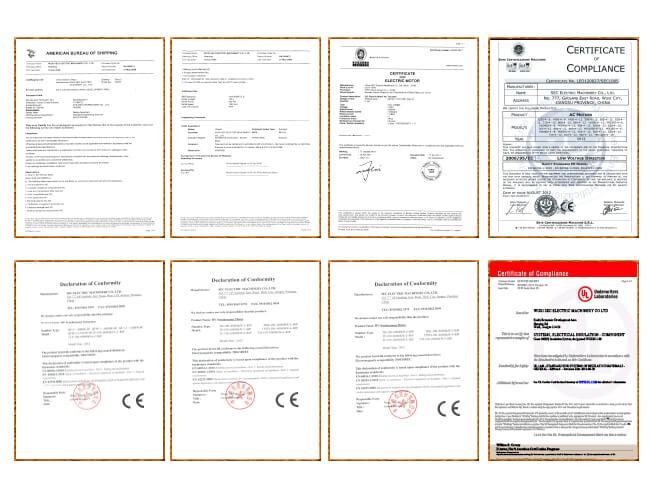

The motor products manufactured by our company have obtained the ISO9001 quality management management system certification, passed the CCC/COC, China energy-saving product certification, and passed the certification certificates of CE/UL/IRIS/CAS and other European and American countries. The company strictly improves the quality and efficient motor products and services for users in strict accordance with the requirements of relevant product standards.

1. The outer packaging of the products are all standard export-oriented wooden plywood packaging.

2, the product packaging is protected by moisture, water plastic soft packaging

3. For products with special transportation requirements (such as temperature, fragile, variability, and easy to get wet), the packaging protection measures will be strengthened, and the target mark will be printed on the package.

4. There are obvious signs and symbols on the packing box that must be paid attention to during transportation and storage (such as position, moisture, rain, shockproof, lifting position, etc.).

NEMA Motor

NEMA series ultra-high-efficiency three-phase asynchronous motor has the advantages of simple structure, flexible control, high system efficiency and remarkable energy saving effect.

NEMA Motor

NEMA series ultra-high-efficiency three-phase asynchronous motor has the advantages of simple structure, flexible control, high system efficiency and remarkable energy saving effect.

IE2 Motor

IE2 motor is a general-purpose fully enclosed fan-cooled squirrel-cage three-phase asynchronous motor, and its efficiency reaches China GB18613-2012 Level 3 energy efficiency or IEC60034-30 standard level 2 energy efficiency.

IE2 Motor

IE2 motor is a general-purpose fully enclosed fan-cooled squirrel-cage three-phase asynchronous motor, and its efficiency reaches China GB18613-2012 Level 3 energy efficiency or IEC60034-30 standard level 2 energy efficiency.

IE3 Motor

IE3 ultra-high efficiency motor adopts high magnetic permeability and low loss cold-rolled non-oriented silicon steel sheet, which is characterized by ultra-high efficiency, energy saving, low vibration, low noise, reliable performance and convenient installation and maintenance.

IE3 Motor

IE3 ultra-high efficiency motor adopts high magnetic permeability and low loss cold-rolled non-oriented silicon steel sheet, which is characterized by ultra-high efficiency, energy saving, low vibration, low noise, reliable performance and convenient installation and maintenance.

Induction Motor

Induction motor, also known as asynchronous motor, that is, the rotor is placed in a rotating magnetic field, under the action of a rotating magnetic field, a rotational moment is obtained, and thus the rotor rotates.

Induction Motor

Induction motor, also known as asynchronous motor, that is, the rotor is placed in a rotating magnetic field, under the action of a rotating magnetic field, a rotational moment is obtained, and thus the rotor rotates.

Asynchronous Motor

YE3 ultra-high efficiency three-phase asynchronous motor adopts high magnetic permeability and low loss cold-rolled non-oriented silicon steel sheet, which is characterized by ultra-high efficiency, energy saving, low vibration, low noise, reliable performance and convenient installation and maintenance.

Asynchronous Motor

YE3 ultra-high efficiency three-phase asynchronous motor adopts high magnetic permeability and low loss cold-rolled non-oriented silicon steel sheet, which is characterized by ultra-high efficiency, energy saving, low vibration, low noise, reliable performance and convenient installation and maintenance.

Low voltage high power squirrel cage motor

Low-voltage high-power squirrel cage motor frame 315-560mm, power 200KW-1500KW, cooling method IC411, high efficiency and energy saving.

Low voltage high power squirrel cage motor

Low-voltage high-power squirrel cage motor frame 315-560mm, power 200KW-1500KW, cooling method IC411, high efficiency and energy saving.

AC Motors

IEC standard electric motors, energy efficiency standards IE2, IE3, IE4, fully enclosed TEFC.

AC Motors

IEC standard electric motors, energy efficiency standards IE2, IE3, IE4, fully enclosed TEFC.

Copyright © ZCL Electric Motor Technology Co., Ltd. All Rights Reserved | Sitemap | Powered by