A Wound Rotor Motor, also known as a Slip Ring Motor, is an electric motor with a unique rotor design that sets it apart from other types of motors. Unlike standard motors with permanent magnets or squirrel-cage rotors, the wound rotor motor features a rotor with windings that have electrical connections to external slip rings.

Brand: ZCL

Product Origin: China

Delivery Time: 20-50 days

Supply Capacity: 500 units/month

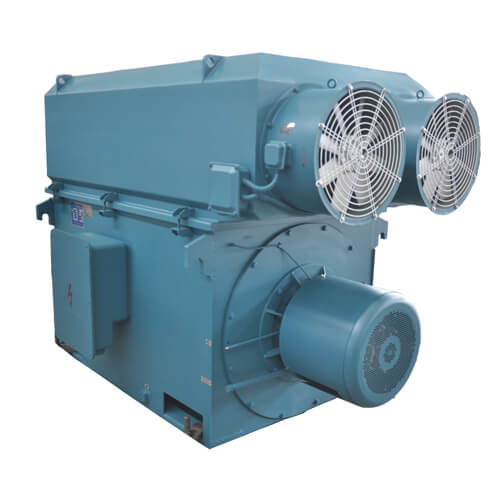

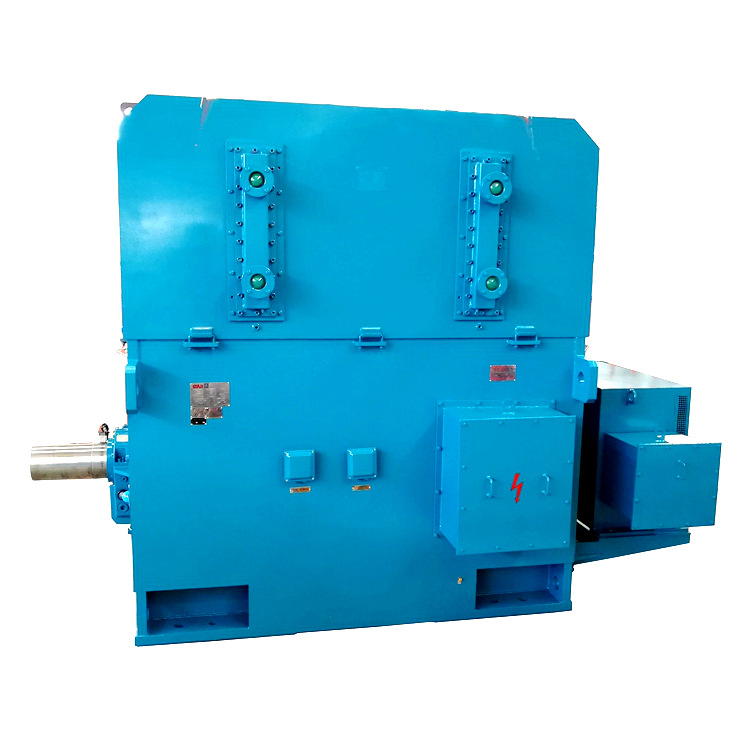

The ZCL Wound Rotor Slip Ring Motor is a specialized type of 3-phase AC motor designed for high starting torque and adjustable speed. Unlike squirrel cage motors, the Wound Rotor Slip Ring Motor features external resistance connected to the rotor circuit, providing unique advantages for industrial applications requiring controlled torque and speed. Our JR winding slip ring motor casing is a cast iron casing or a steel plate welded casing with high structural strength and good mechanical properties. The motor shaft extension end and the non-bearing end have an inlet and outlet air outlet, and the motor slip ring is located at the non-bearing end. The series of motors has a simple structure, convenient installation, convenient maintenance, large starting torque and safe and reliable operation. JR winding slip ring motors can drive a variety of different machines, such as fans, compressors, pumps, crushers, ball mills, winches, hoists, transport machinery and other equipment, as well as mines, machinery, power plants and are Used as the prime mover in various industrial and mining enterprises.

The JR series motor is a Wound Rotor Motor. This series of motors meet the technical standard conditions. It can drive a variety of different machines, such as fans, compressors, pumps, crushers, ball mills, cutting machines, transport machinery and other equipment. It is used as a prime mover in the machinery industry, power plants and various industrial and mining enterprises. The rating of the JR winding slip ring motor is based on the continuous working system (S1). The frequency is 50HZ, the rated voltage is 220V/380V, 380V, 415V, 3000V, 6000V, which can be designed to 3300V/10000V according to the needs of users.

The protection of this series of Wound Rotor Motor is IP23; the cooling method is IC01; the structure and installation method of the motor is generally IMB3, and it can also be designed as vertical installation according to customer requirements.

The ratio of the maximum torque to the rated torque of the JR winding slip ring motor at the rated voltage is not less than 1.8.

The JR winding slip ring motor must be connected to the starting varistor in the rotor circuit at the start. It is not permissible to short-circuit the rotor windings directly.

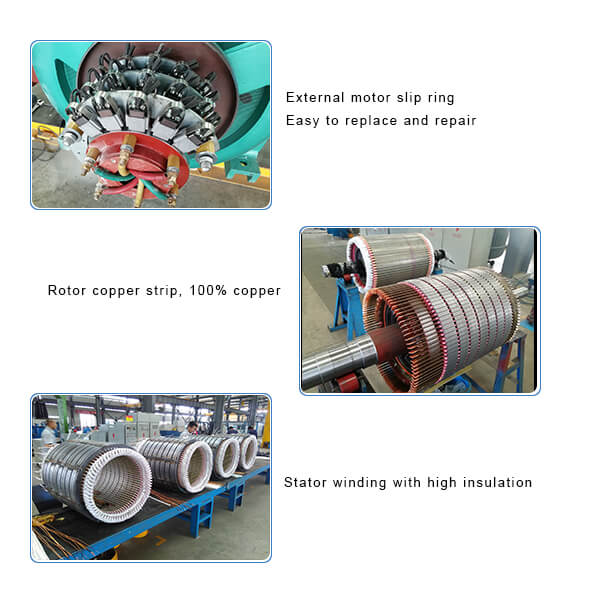

The JR series Wound Rotor Slip Ring Motor features a protective winding type rotor and a continuous working system (S1). It is equipped with:

Casing: Cast iron or steel plate welded casing for high structural strength.

Cooling Method: IC01 for effective cooling.

Protection Level: IP23, suitable for controlled environments.

Rotor Design: Three-phase insulated windings connected to slip rings via brushes.

Stator Design: Similar to a 3 Phase Cage Induction Motor, ensuring efficient operation.

Motor Power Range: 80KW-850KW

Rated Voltage: 380V/415V/660V/690V/3000V/6000V/10000V

Number of Poles: 6/8/10/12

Rated Frequency: 50Hz/60Hz

Working System: S1

Insulation Class: B

Ambient Temperature: ≥ -15°C and ≤ 40°C

ZCL Wound Rotor Motor is suitable for altitudes up to 1000 m and the ambient air temperature is 0-40 degrees. The protective motor should be installed in a room with clean air, no dust, steam, acid, alkali and other corrosive gases. It is not allowed to be used in an environment containing explosive gas or dust.

The slip ring design allows for high starting torque, making it suitable for heavy-duty applications such as:

Lifts

Cranes

Elevators

Mills

By varying the external resistance in the rotor circuit, the motor’s speed can be precisely controlled to match specific application requirements.

The external resistance reduces the starting current, ensuring smooth operation even in power systems with limited capacity.

Compared to a Squirrel Cage Rotor, the Wound Rotor Slip Ring Motor offers improved overload capacity, smoother acceleration, and a higher power factor.

The Wound Rotor Slip Ring Motor is versatile and used across various industries, including:

Mining: Powering heavy machinery such as crushers and ball mills.

Power Plants: Driving large fans and pumps.

Industrial Facilities: Operating elevators, hoists, and conveyors.

Specialized Machinery: Supporting equipment with large flywheels, such as punch presses.

Energy Efficiency: While wound rotor motors offer control advantages, they are generally less energy-efficient than squirrel-cage induction motors or permanent magnet motors. As a result, they might not be the first choice for applications where high energy efficiency is a critical factor.

1. The outer packaging of the Wound-Rotor Motor is all standard export-oriented wooden plywood packaging.

2. The Wound-Rotor Motor packaging is protected from moisture, water plastic soft packaging

3. For products with special transportation requirements (such as temperature, fragility, variability, and ease to get wet), the packaging protection measures will be strengthened, and the target mark will be printed on the package.

4. There are obvious signs and symbols on the packing box that must be paid attention to during transportation and storage (such as position, moisture, rain, shockproof, lifting position, etc.).

The company has a large-scale laboratory, intelligent CNC winding machine, CNC rising machine, automatic wrapping machine, VPI high pressure vacuum immersion system, large-scale dipping paint drying furnace, 60 tons test platform, large vertical car, milling machine, grinding machine, Each type of dynamic balancing machine, double-feedback test and detection system with 6MW (12MW) motor and other motor production professional equipment more than 500 sets, sound mechanical equipment processing capacity, to lay a good foundation for customers to improve good quality motor products.

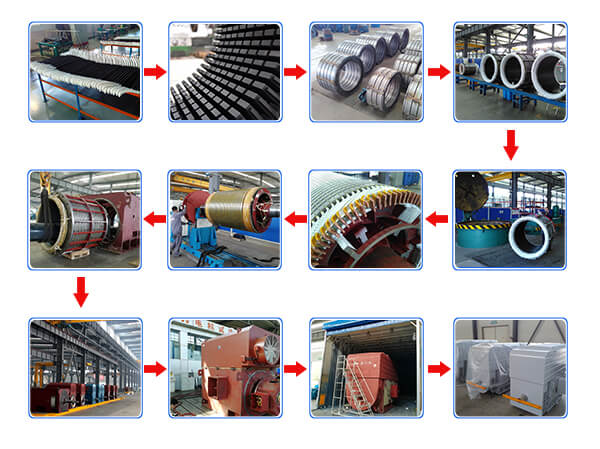

Motor stator: casing processing → punching press → iron core seating → coil making → weaving → dipping paint drying

Electronic rotor: blank shaft processing → iron core press installation → iron core cast aluminum → rotor string shaft → weave → dipping paint drying → dynamic balance

Motor assembly: stator rotor assembly → machine test → motor appearance coloring →packaging storage

Expert Manufacturing: Professional design and adherence to international standards.

Certifications: ISO9001, CCC, CE, and UL certified.

Customer Support: Comprehensive sales and technical service team.

Durable Construction: High mechanical strength and reliable operation.

Cooling Method: IC01

Protection Level: IP23

Installation: Horizontal (IMB3) or vertical upon request

The ZCL Wound Rotor Slip Ring Motor is a reliable, high-performance solution for applications requiring high starting torque and adjustable speed. Its robust design and efficiency make it a superior choice over other motors, including the 3 Phase Cage Induction Motor and Squirrel Cage Rotor Motor. Whether for mining, industrial, or specialized machinery, this motor delivers unparalleled performance. Contact us to learn more about our Wound Rotor Slip Ring Motor and how it can benefit your operations.

Wound Rotor Slip Ring Motor

A Wound Rotor Motor, also known as a Slip Ring Motor, is an electric motor with a unique rotor design that sets it apart from other types of motors. Unlike standard motors with permanent magnets or squirrel-cage rotors, the wound rotor motor features a rotor with windings that have electrical connections to external slip rings.

Wound Rotor Slip Ring Motor

A Wound Rotor Motor, also known as a Slip Ring Motor, is an electric motor with a unique rotor design that sets it apart from other types of motors. Unlike standard motors with permanent magnets or squirrel-cage rotors, the wound rotor motor features a rotor with windings that have electrical connections to external slip rings.

Slip Ring Motor for Ball Mill

YRQ winding slip ring motor is specially designed for ball mill. This series of motors is a derivative of the original JR slip ring motor.

Slip Ring Motor for Ball Mill

YRQ winding slip ring motor is specially designed for ball mill. This series of motors is a derivative of the original JR slip ring motor.

YR Series (IP44) Slip Ring Induction Motor

YR series (IP44) slip ring induction motor is a general-purpose wound rotor three-phase asynchronous motor. It is the latest design and updated product.

YR Series (IP44) Slip Ring Induction Motor

YR series (IP44) slip ring induction motor is a general-purpose wound rotor three-phase asynchronous motor. It is the latest design and updated product.

AC Slip Ring Motor

YR series AC slip ring (IP23) motor is a protective wound rotor asynchronous motor.

AC Slip Ring Motor

YR series AC slip ring (IP23) motor is a protective wound rotor asynchronous motor.

415V Slip Ring Motor

YZR series motors are hoisting metallurgy special winding slip ring AC motors.

415V Slip Ring Motor

YZR series motors are hoisting metallurgy special winding slip ring AC motors.

Hot Selling Slip Ring Motor

The YR3 series (IP54) slip ring motor is a closed-wound rotor three-phase asynchronous motor, which is a new generation of design.

Hot Selling Slip Ring Motor

The YR3 series (IP54) slip ring motor is a closed-wound rotor three-phase asynchronous motor, which is a new generation of design.

Asynchronous Slip Ring Motor

The asynchronous slip ring motor is a high voltage wound three-phase asynchronous motor.

Asynchronous Slip Ring Motor

The asynchronous slip ring motor is a high voltage wound three-phase asynchronous motor.

Heavy Duty High Voltage Slip Ring Motor

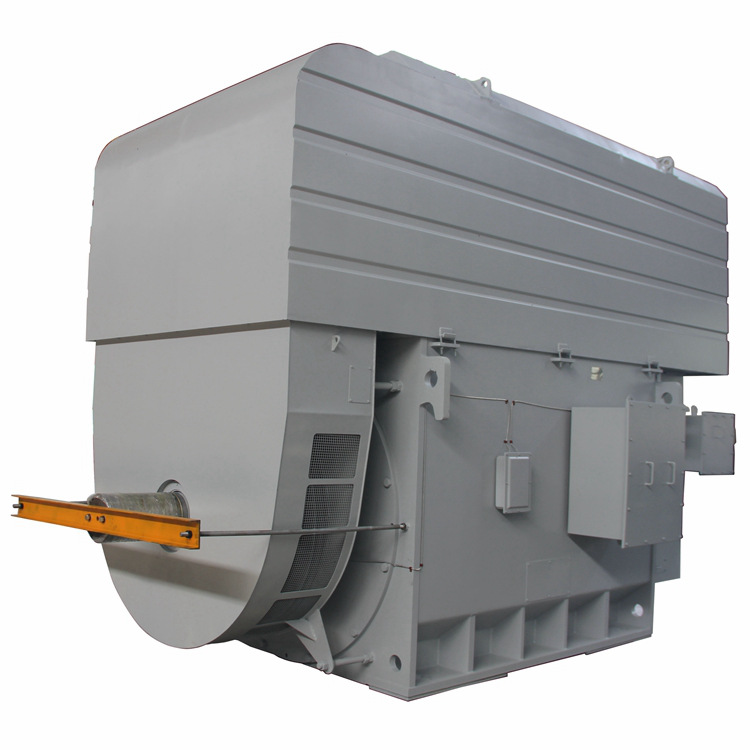

YR series heavy-duty high-voltage slip ring motor (open type) is a steel plate welding machine base, horizontal structure large-winding three-phase asynchronous motor.

Heavy Duty High Voltage Slip Ring Motor

YR series heavy-duty high-voltage slip ring motor (open type) is a steel plate welding machine base, horizontal structure large-winding three-phase asynchronous motor.

Slip Ring Induction Motor

The mechanical strength of the slip ring induction motor winding is high, which improves the insulation level of the motor. The slip ring and carbon brush device of the motor are placed outside the end cover, which can effectively prevent carbon dust from contaminating the coil. At the same time, it is also easy to replace the repair.

Slip Ring Induction Motor

The mechanical strength of the slip ring induction motor winding is high, which improves the insulation level of the motor. The slip ring and carbon brush device of the motor are placed outside the end cover, which can effectively prevent carbon dust from contaminating the coil. At the same time, it is also easy to replace the repair.

Slip Ring Motor Suppliers

The slip ring motor is a wound three-phase asynchronous motor.

Slip Ring Motor Suppliers

The slip ring motor is a wound three-phase asynchronous motor.

Slip Ring Motor

The slip ring motor is a wound high-voltage asynchronous motor (frame size 355-1000).

Slip Ring Motor

The slip ring motor is a wound high-voltage asynchronous motor (frame size 355-1000).

Slip Ring Motor

YRKK series motors are slip-surrounding three-phase asynchronous motors, which can increase the starting torque at a small starting current.

Slip Ring Motor

YRKK series motors are slip-surrounding three-phase asynchronous motors, which can increase the starting torque at a small starting current.

High Quality Slip Ring Motor

The high-quality slip ring motor adopts box-type structure.

High Quality Slip Ring Motor

The high-quality slip ring motor adopts box-type structure.

Wound Rotor Motor

The Wound Rotor Motor is a high-pressure slip ring motor developed and manufactured by our company for many years.

Wound Rotor Motor

The Wound Rotor Motor is a high-pressure slip ring motor developed and manufactured by our company for many years.

High-voltage Wound Rotor Slip Ring Motor

The high-voltage wound rotor slip ring motor is a high-voltage three-phase asynchronous motor developed and manufactured by our company for many years.

High-voltage Wound Rotor Slip Ring Motor

The high-voltage wound rotor slip ring motor is a high-voltage three-phase asynchronous motor developed and manufactured by our company for many years.

6kv Slip Ring Motor

6KV slip ring motor is a high-voltage wound rotor three-phase asynchronous motor developed and manufactured by our company for many years.

6kv Slip Ring Motor

6KV slip ring motor is a high-voltage wound rotor three-phase asynchronous motor developed and manufactured by our company for many years.

High Voltage Slip Ring Induction Motor

YRKK series HV slip ring induction motors are used in the motors of heavy-duty starting equipment such as ball mills, rolling mills, sugar mills, crushers, etc.

High Voltage Slip Ring Induction Motor

YRKK series HV slip ring induction motors are used in the motors of heavy-duty starting equipment such as ball mills, rolling mills, sugar mills, crushers, etc.

High Voltage Wound Rotor Induction Motor

YRKS series High Voltage Wound Rotor Induction Motor are used in the motors of heavy-duty starting equipment such as ball mills, rolling mills, sugar mills, crushers, etc.

High Voltage Wound Rotor Induction Motor

YRKS series High Voltage Wound Rotor Induction Motor are used in the motors of heavy-duty starting equipment such as ball mills, rolling mills, sugar mills, crushers, etc.

JR slip ring motor for ball mill

JR ball mill motor adopts rotor string resistance full-voltage start-up, which has the advantages of small starting current, large starting torque, high efficiency, low noise, low vibration, good ventilation performance, reliable operation, convenient installation and maintenance.

JR slip ring motor for ball mill

JR ball mill motor adopts rotor string resistance full-voltage start-up, which has the advantages of small starting current, large starting torque, high efficiency, low noise, low vibration, good ventilation performance, reliable operation, convenient installation and maintenance.

Copyright © ZCL Electric Motor Technology Co., Ltd. All Rights Reserved | Sitemap | Powered by