Brand: ZCL

Product Origin: China

Delivery Time: 45-90 days

Supply Capacity: 50 units/month

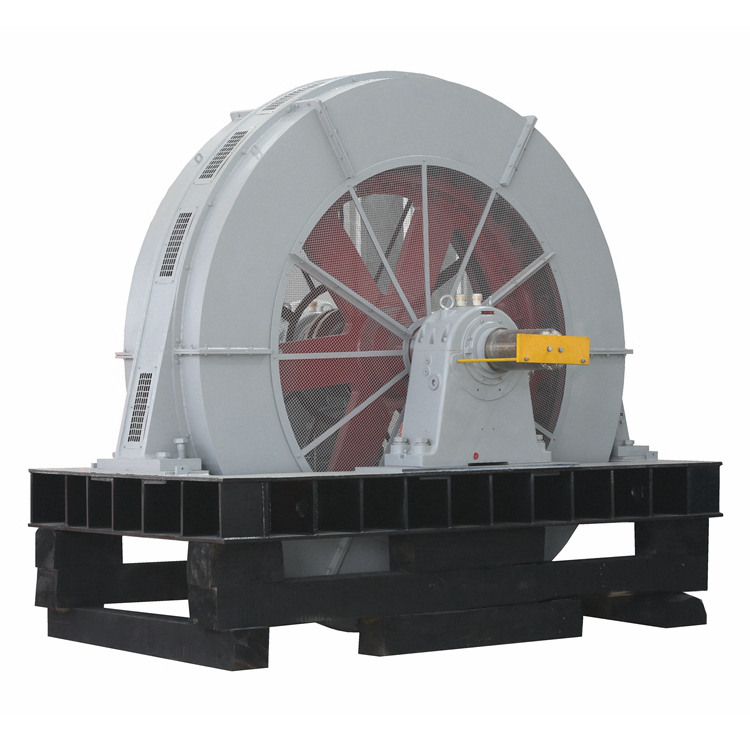

The 32-pole mine TDMK synchronous motor ventilation mode is open natural ventilation or can be made into a fully enclosed pipeline ventilation type.

TDMK series mine high-voltage synchronous motor base: welded by steel plate, the lower part of the base is the outlet end of the motor.

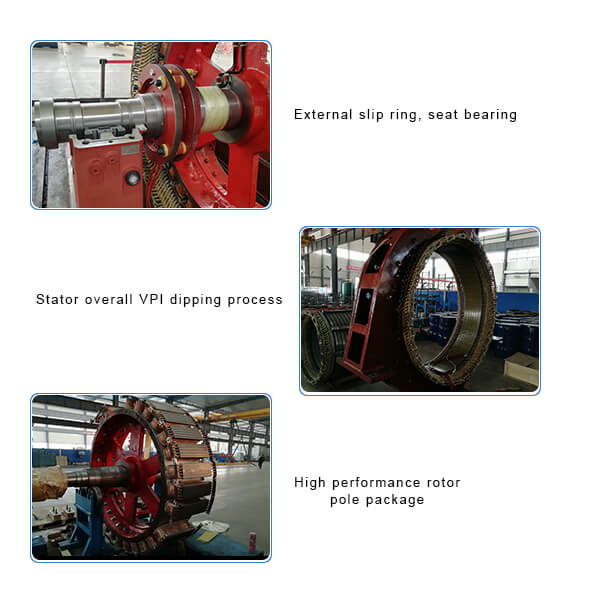

The stator core of TDMK series 400KW mining synchronous motor is made up of fan-shaped pieces punched by 0.5 mm thick low-loss silicon steel sheet, and the core segments are separated by radial ducts; the windings are formed by double-stack winding short-span coils. Use Class B insulation or Class F insulation, temperature rise according to Class B assessment to facilitate extended service life; winding ends are reliably fixed and tied, and vacuum pressure impregnated solventless paint process (VIP) treatment, in the manufacturing process Repeated inter-turn pulse withstand voltage and ground pressure test, motor insulation performance is excellent and reliable, mechanical strength is good, moisture resistance is strong.

The rotor of the synchronous ball mill of the mine ball mill: the magnetic pole is made of steel plate and is mounted on the rotor yoke together with the magnetic pole coil. The magnetic pole coil is B-class or F-class insulation. When the user adopts the pneumatic clutch, the rotary shaft can be customized according to the user's requirements. Design or shaft punching type (the center is long through hole, the shaft end is blocked, the shaft head is equipped with an air clutch, and the other end is machined with a stop and bolt hole as required, and is connected to the rotary joint of the air clutch).

TDMK series high-voltage mine ball mill synchronous motor is suitable for working in indoor environment where the altitude is not more than 1000m, the temperature of the cooling medium is not more than 40 degrees, less dust, no corrosive gas such as steam, acid or alkali. This series of motors is rated at 6000V and can also be supplied with 3000V and 10000V according to user requirements. The allowable voltage has a deviation range of +5%, the rated power supply frequency is 50 Hz, and the rated power factor is 0.9 (leading).

The TDMK series mining synchronous motor has a cylindrical shaft extension end, and its rotation direction should be rotated in the direction specified by the sign. The direction of rotation is generally counterclockwise from the end of the collector ring, and can also be made clockwise according to requirements. When the motor and the mill are coupled by a coupling, the motor shaft cannot be extended to withstand external radial or axial forces.

The mining synchronous motor excitation system uses a thyristor excitation device.

The mine high voltage synchronous motor allows full voltage to be started directly. If the user's power grid does not allow the full voltage to start directly, the step-down start can also be used. At this time, the starting current of the motor decreases in proportion to the terminal voltage, and the starting torque decreases in proportion to the square of the terminal voltage.

TDMK series 400KW synchronous motor stator lead-out line: There are six outlet heads, namely U1, V1, W1, U2, V2, W2, which are led out on the lower output clamp of the base by high-voltage rubber cable, or can be made as required. Box wiring.

This series of synchronous motor seat bearings: oil ring bearings or composite bearings, seat bearings are installed between the bottom plate with insulation pads to prevent the generation of shaft current.

The TDMK series motors are mainly suitable for large AC three-phase synchronous motors used in transmission mine mills. The main transmission lattice ball mill, rod mill, coal mill mining equipment. The main motor is coupled with the pinion through the air clutch to realize a single-stage reduction transmission to drive the rotation of the rotary part.

Product Parameters

Motor name: TDMK400-32

Rated power: 400KW

Rated speed: 187.5 r/min

Rated voltage: 10000V (can also be made into other grades)

Rated frequency: 50HZ

Power factor: 0.9 (leading)

Rated current: 28.5A

Excitation voltage: 83.9V

Excitation current: 184.8A

Insulation class: B

Temperature rise level: B

Protection level: IP00/IP21

Installation method: IM7311

Working system: S1

Weight: 11000kg

Excitation mode: static thyristor, other excitation methods can also be used

Connection: Y

Cooling method: IC01.

Other forms of motors can also be produced according to user requirements, such as duct ventilation and air and air cooling.

Mine synchronous motor use elevation: no more than 1000m, the motor can be installed according to the requirements of temperature measurement, heater, impact protection and other devices. The allowable voltage has a deviation range of ± 5%, because the power factor is ahead of the grid, which has a certain compensation effect on the grid. This type of motor is suitable for use in environments where the ambient air temperature does not exceed 40 ° C and there is no serious dust, the minimum ambient air temperature is -15 ° C, and there is no corrosive and explosive gas in the air (which can also be made into a damp heat or high-altitude motor).

Feature of Product

TDMK mining synchronous motors have high starting torque and high out-of-step torque. The motor has an advanced power factor (which improves grid power factor), high efficiency, high stability and high overload capability, and has the performance that the speed does not change with load.

Equipment Capacity

The company has large-scale laboratory, intelligent CNC winding machine, CNC rising machine, automatic wrapping machine, VPI high pressure vacuum immersion system, large-scale dipping paint drying furnace, 60 tons test platform, large vertical car, milling machine, grinding machine, Each type of dynamic balancing machine, double-feedback test and detection system with 6MW (12MW) motor and other motor production professional equipment more than 500 sets, sound mechanical equipment processing capacity, to lay a good foundation for customers to improve good quality motor products.

Product Use

The motor products manufactured and sold by our company are used in many industries, such as electric power, mining, steel metallurgy, petrochemical, water conservancy, transportation, building materials and many other industries. The equipment for the motor is pump, machine tool, fan, mill, crusher, rolling mill, compressor and many other industrial equipment.

About Us

Shijiazhuang ZCL Electric Motor Technology Co., Ltd. is a company mainly engaged in the manufacture, research and development and sales of motor products. The company has many types of motor products, including IEC standard motors. It is a professional IEC motor manufacturer. Related motor products have passed the product certification in China, the United States, Canada, Europe, the Middle East and other regions, and the products are exported to all over the world. Companies adhere to the "focus on products, service" business philosophy, is committed to improving the quality of safe motor products and services for customers around the world.

FAQ

More details, welcome to call us!

Q: What are the payment terms?

A: 30% T/T in advance, 70% before shipment

Q: What is your delivery time?

A: Different models with different time, 10-90 days after order confirmed.

Q: What is your MOQ?

A: It depends on model.

Q: Where is your loading port?

A: Shanghai or Tianjing Port, China.

Synchronous Motor Manufacturer

Large high-voltage synchronous motors are ventilated by open natural ventilation or can be made into fully enclosed ducted ventilation.

Synchronous Motor Manufacturer

Large high-voltage synchronous motors are ventilated by open natural ventilation or can be made into fully enclosed ducted ventilation.

Synchronous Motor Supplier

Large high-voltage synchronous motors are ventilated by open natural ventilation or can be made into fully enclosed ducted ventilation.

Synchronous Motor Supplier

Large high-voltage synchronous motors are ventilated by open natural ventilation or can be made into fully enclosed ducted ventilation.

Synchronous 4 and 6 Poles Motors

The T Series 4 and 6 pole high speed synchronous motors are horizontal.

Synchronous 4 and 6 Poles Motors

The T Series 4 and 6 pole high speed synchronous motors are horizontal.

Synchronous Motors for Air Separation Applications

TK series three-phase synchronous motor is a high-voltage synchronous motor specially designed for air compressors, mainly used in refrigeration and fertilizer industry equipment.

Synchronous Motors for Air Separation Applications

TK series three-phase synchronous motor is a high-voltage synchronous motor specially designed for air compressors, mainly used in refrigeration and fertilizer industry equipment.

TDMK large synchronous slip ring motor for ball mill

This series of ball mill synchronous motor is mainly suitable for large AC three-phase synchronous motor used in transmission mine mill. The main transmission lattice ball mill, rod mill, coal mill mining equipment.

TDMK large synchronous slip ring motor for ball mill

This series of ball mill synchronous motor is mainly suitable for large AC three-phase synchronous motor used in transmission mine mill. The main transmission lattice ball mill, rod mill, coal mill mining equipment.

40p 1600KW High Voltage Permanent Magnet Synchronous Motor

The drive mode of 40p-1600KW high-voltage permanent magnet synchronous motor adopts the pinion of permanent magnet motor directly driven ball mill, which can greatly improve work efficiency and running cost.

40p 1600KW High Voltage Permanent Magnet Synchronous Motor

The drive mode of 40p-1600KW high-voltage permanent magnet synchronous motor adopts the pinion of permanent magnet motor directly driven ball mill, which can greatly improve work efficiency and running cost.

Synchronous 8 to 40 Poles Motors

The 8 to 40 pole synchronous motor is a horizontal three-phase salient-pole synchronous motor.

Synchronous 8 to 40 Poles Motors

The 8 to 40 pole synchronous motor is a horizontal three-phase salient-pole synchronous motor.

Large Synchronous Excitation Electric Motor

The large synchronous motor is a horizontal three-phase salient-pole synchronous motor. The installation method of the motor is horizontal installation. The outer casing of the motor has a circular structure, the protection grade is IP20, and the cooling mode is open ventilation cooling.

Large Synchronous Excitation Electric Motor

The large synchronous motor is a horizontal three-phase salient-pole synchronous motor. The installation method of the motor is horizontal installation. The outer casing of the motor has a circular structure, the protection grade is IP20, and the cooling mode is open ventilation cooling.

Synchronous Motors for Mining Applications

Large-scale synchronous motor ventilation for mines is open-type natural ventilation or can be made into fully enclosed pipeline ventilation.

Synchronous Motors for Mining Applications

Large-scale synchronous motor ventilation for mines is open-type natural ventilation or can be made into fully enclosed pipeline ventilation.

Copyright © ZCL Electric Motor Technology Co., Ltd. All Rights Reserved | Sitemap | Powered by