A large number of synchronous motors and generators are now available for a wide range of industrial applications. Electric motors have become an integral part of industrial production. They convert electrical energy into mechanical energy, enabling industrial machines to perform the tasks assigned to them. Not all electric motors perform similar tasks, but some of them are specifically designed for specific industries.

In addition to the many different functions offered by well-designed motors, the tasks performed in industry are perhaps the most complex. Some electric motors are used for coal mining, while some provide energy for crushing and shredding in the cement industry. For steel mills, on the other hand, stable inputs are needed to ensure the continuity of their production processes in an extremely warm atmosphere. For this reason, they often use special motors for conveyor belts. The sugar industry relies on customized high-voltage motors or IE4 super premium motors, as they can provide higher voltages without much electrical energy.

Electric motors are used not only to provide the grounds and equipment, but also to drive various production machines. The motors below are the ones that drive propellers, turn turbines or inhale smoke and debris in crowded public or private environments. In water plants, it is electric motors that help pump water. In addition, advanced three-phase motors are used in compressors because they can cool themselves sufficiently to withstand higher temperatures. These advantages also make them the perfect choice for industrial boilers.

This is the definition of a synchronous motor: an AC motor in which, at rest, the rotation of the shaft is synchronized with the frequency of the applied current.

Synchronous motors are not applicable to induction currents. Unlike induction motors, these motors have multi-phase AC magnets in the stator that produce a rotating magnetic field. In this case, the rotor has permanent magnets that are synchronized with the rotating magnetic field and rotate synchronously with the frequency of the supplied current.

The function of a synchronous motor is based on the interaction of the stator magnetic field with the rotor magnetic field. The three-phase winding is contained in the stator and operates with a three-phase current. The stator winding thus generates a three-phase rotating magnetic field. The rotor is powered by DC current.

If the load is greater than the fault load, the motor is not synchronized. Three-phase stator windings have the advantage of determining the direction of rotation. For single-phase windings, there is no need to determine the direction of rotation and the motor can be started in both directions. The starting device is necessary to control the direction of rotation of these synchronous motors.

Synchronous motors are typically used in applications where constant and precise speed is required. Typical applications for these low power motors are positioning machines. They are also used in robot actuators. Synchronous motors are also used in ball mills, watches, jukeboxes and turntables. They are also used as servo motors and timing machines.

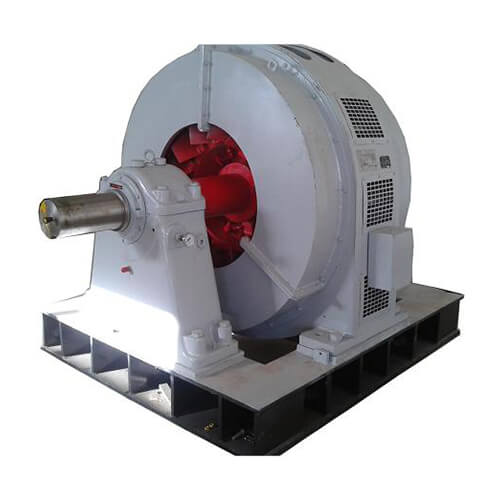

These motors range from horseshoe sizes to industrial high performance sizes. Although they are used in industrial high performance sizes, these motors are capable of performing two basic functions. One is as an efficient means of converting AC energy into mechanical energy, and the other is as a power factor correction.

ZCL is a modern import and export company integrating technical research and technical consultation of electrical equipment, mechanical equipment and automation control equipment. Our main products are large high voltage motors, slip ring motors, synchronous motors, please contact us if you need to buy.

Copyright © ZCL Electric Motor Technology Co., Ltd. All Rights Reserved | Sitemap | Powered by